Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

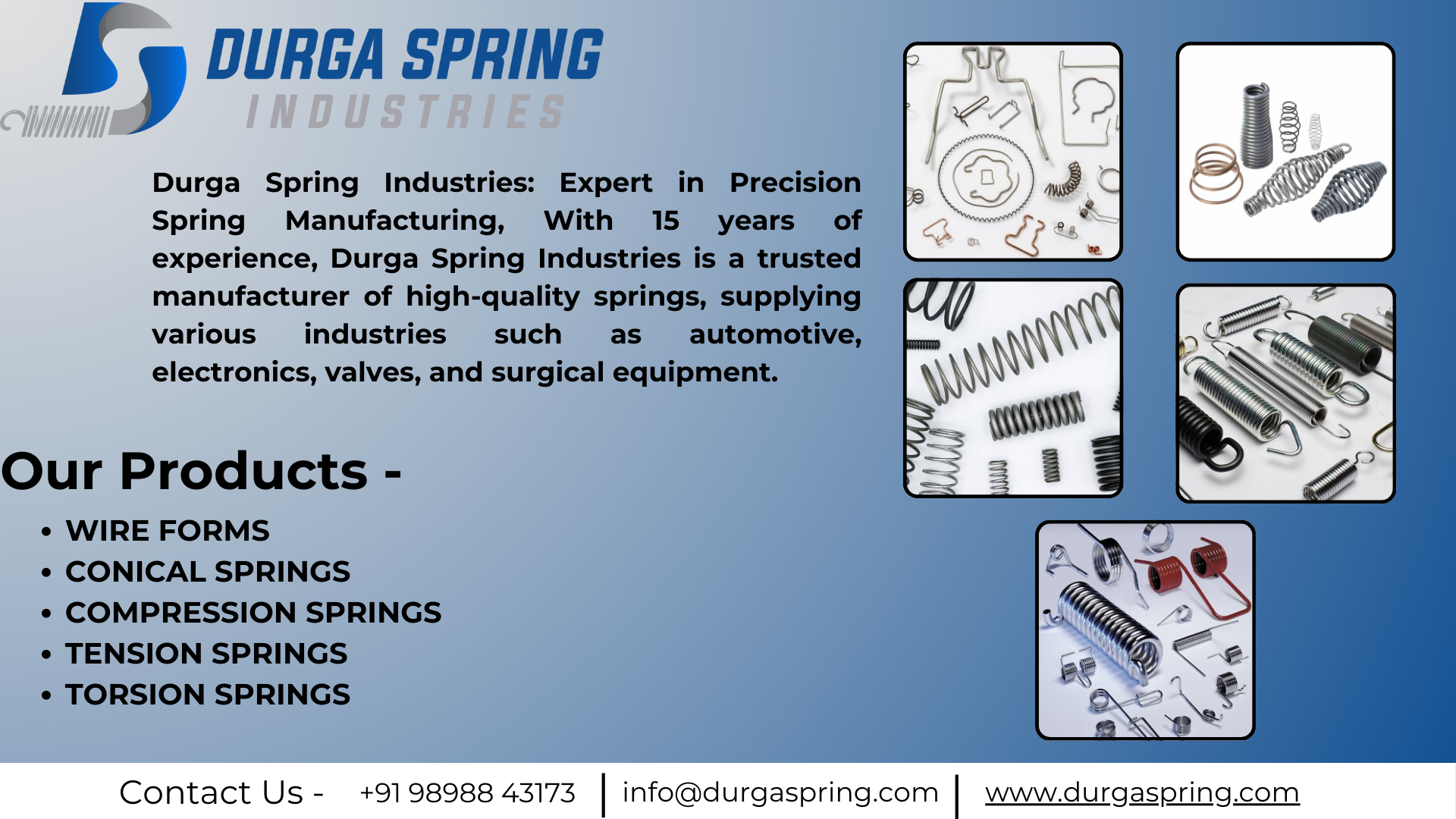

As a prominent Ahmedabad-based spiral spring manufacturer, Durga Spring is strategically positioned to serve the high-demand industrial sector of Gujarat. We specialize in producing precision flat spiral springs, power springs, and constant force springs that are critical for various winding mechanisms, counterbalances, and energy storage applications. Our commitment to quality, coupled with local manufacturing efficiency, makes us the preferred power springs supplier in Gujarat. We ensure that every spring meets exact force and lifespan specifications, providing reliable mechanical solutions to local and national clients.

Our strength as a leading custom spiral springs India provider lies in our advanced manufacturing process, designed for precision and volume:

Choosing an **Ahmedabad-based spiral spring manufacturer** like Durga Spring means selecting a partner dedicated to local business growth and component excellence. Our proximity allows for quicker design reviews, faster delivery, and superior technical support. Whether you require standard **Flat Spiral Springs Ahmedabad** or highly customized solutions, we are equipped to deliver precision and performance directly to your facility in Gujarat. Contact us to discuss your spring requirements and benefit from our localized expertise.

Durga Spring• We’re here to help

Filter Using Product Tags