Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

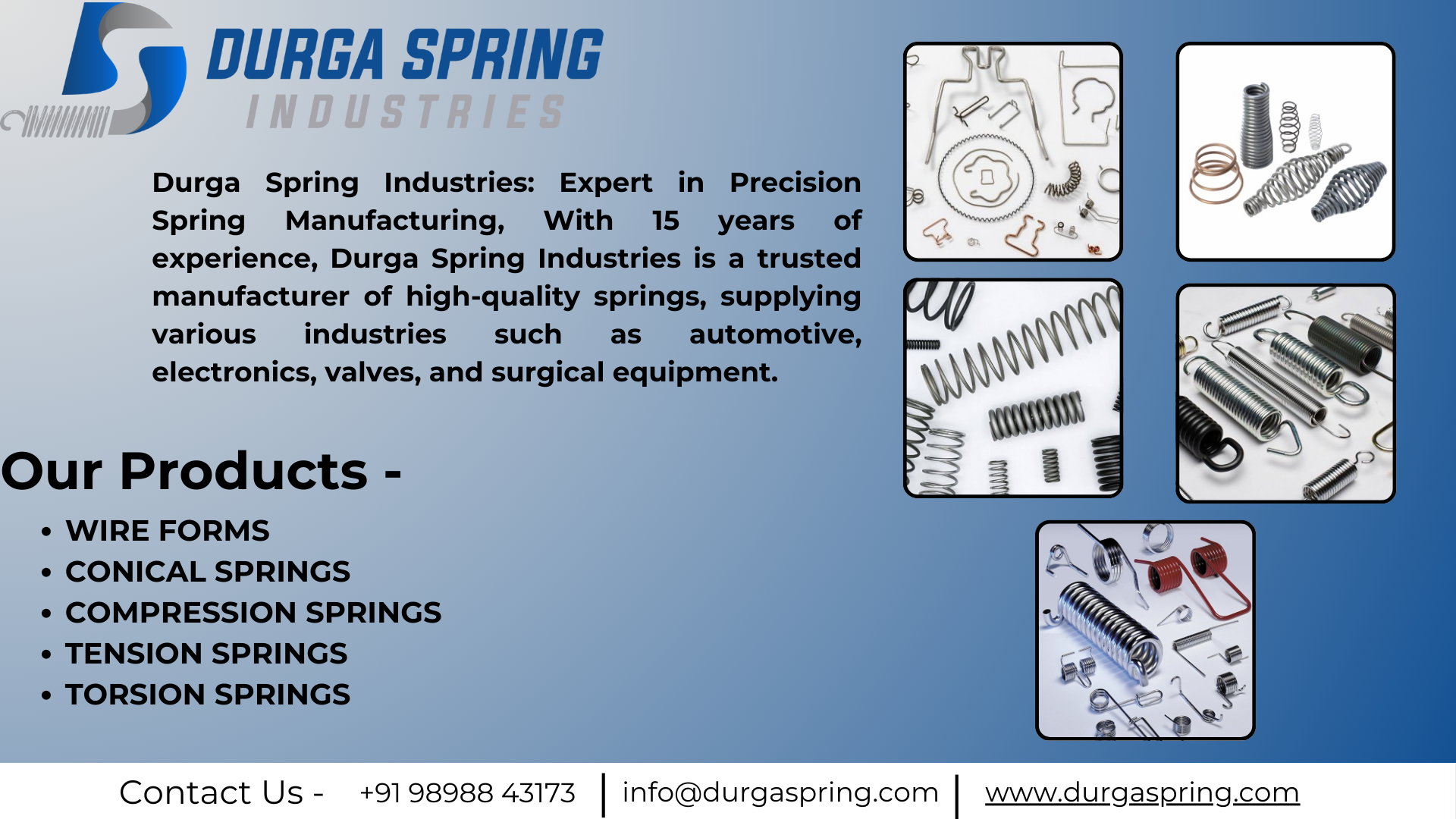

Durga Spring Industries is a trusted affordable torsion spring manufacturer in India, delivering precision-engineered springs at competitive prices without compromising quality. From prototyping to bulk production, we manufacture custom torsion springs for automotive, electronics, valves, medical devices, and industrial machinery. Our CNC coiling, heat treatment, and strict quality checks ensure consistent torque, long life, and cost-efficiency—making us a preferred supplier for OEMs and MSMEs across India.

Torsion springs store energy when twisted and release torque to control rotational motion. We start with certified wire, then CNC-coil to tight tolerances, heat-treat for strength, stress-relieve for durability, and finish for corrosion resistance. Each batch undergoes load/torque testing and dimensional audits. Our lean production and material optimization help reduce cost per piece while maintaining accuracy—ideal for high-volume buyers seeking affordable yet reliable springs.

India’s spring industry offers strong capability in precision torsion springs. Durga Spring Industries distinguishes itself by combining affordable pricing with rigorous quality systems and quick lead times. With CNC production, flexible MOQs, and engineering support, we serve startups to large OEMs nationwide—delivering reliable parts for automotive, electronics, and industrial applications.

Durga Spring• We’re here to help

Filter Using Product Tags