Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

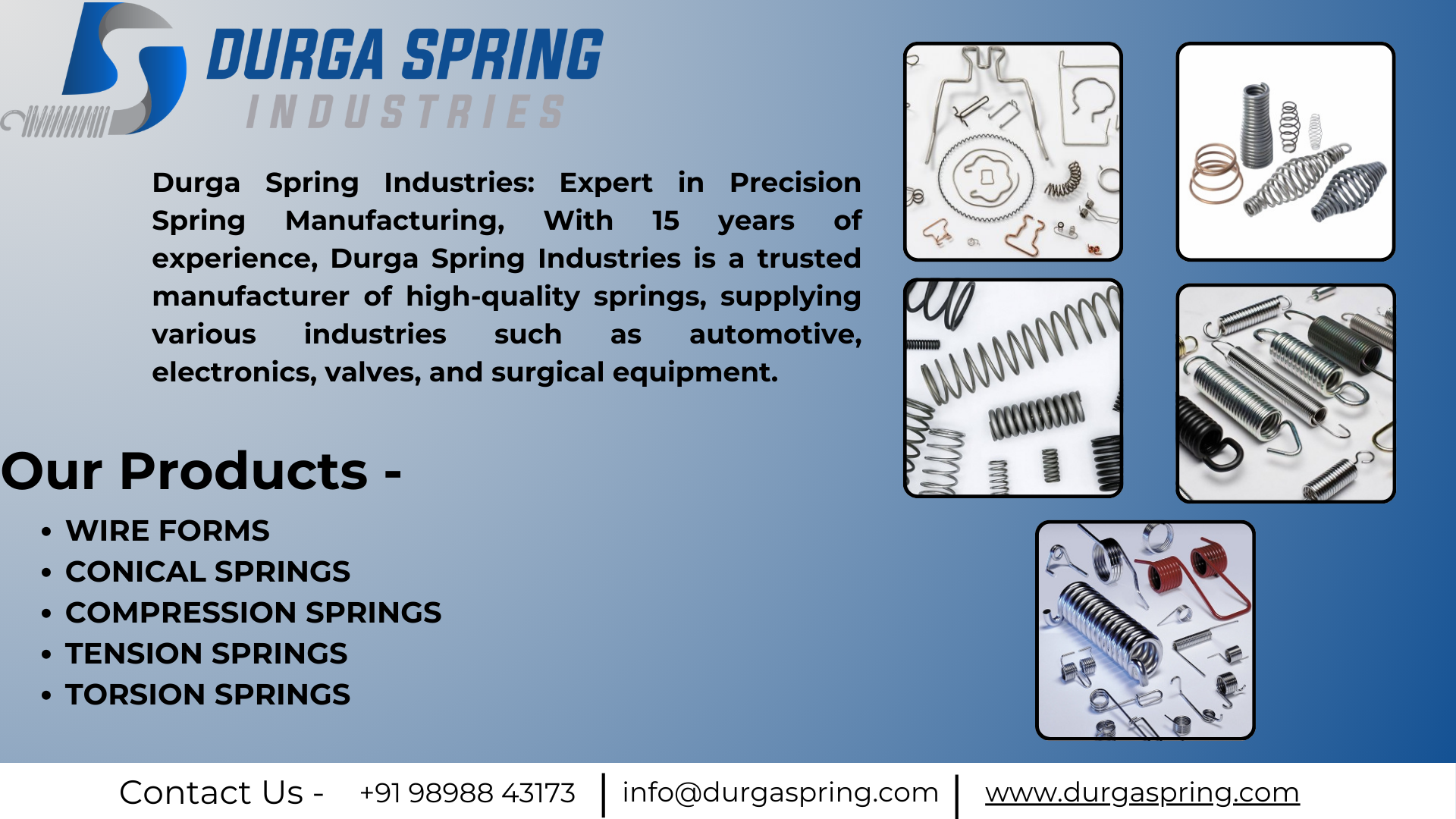

Durga Spring Industries is a leading heavy-duty die springs manufacturer in Ahmedabad, specializing in robust, high-load springs built for the most demanding industrial applications. Our springs are engineered to withstand extreme pressures and repeated cycling, making them ideal for heavy machinery, forging presses, and large-scale dies where standard springs would fail. With over 15 years of expertise and a state-of-the-art facility in Ahmedabad, we provide reliable, durable, and high-performance solutions that ensure safety and efficiency for industries throughout Gujarat and India. Our commitment to quality and precision makes us the go-to supplier for critical heavy-duty spring requirements.

Heavy-duty die springs are designed to handle maximum stress and fatigue, which requires a specialized manufacturing process. At our Ahmedabad facility, we begin with sourcing high-tensile strength materials such as chrome-silicon or chrome-vanadium steel. The wire is precision-coiled and then subjected to an advanced heat treatment process at elevated temperatures to enhance its strength and resilience. This is followed by a shot-peening procedure to improve fatigue life and a final coating with a specific color (typically green or brown) to denote its extra-heavy load rating. This rigorous process ensures that every spring we produce can deliver consistent and reliable performance under extreme operational stress.

In the highly competitive market for industrial components, finding a trusted heavy-duty die springs manufacturer in Ahmedabad is crucial. Durga Spring Industries stands out by offering a product line specifically designed for the most challenging applications. While many suppliers offer standard die springs, our expertise lies in engineering and manufacturing springs that can handle forces far beyond conventional ratings. Our strategic location in Ahmedabad allows us to provide quick delivery and dedicated support to local businesses and key industrial hubs across Gujarat and India, solidifying our reputation as a premier supplier of high-quality, heavy-duty springs.

Durga Spring• We’re here to help

Filter Using Product Tags