Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Precise

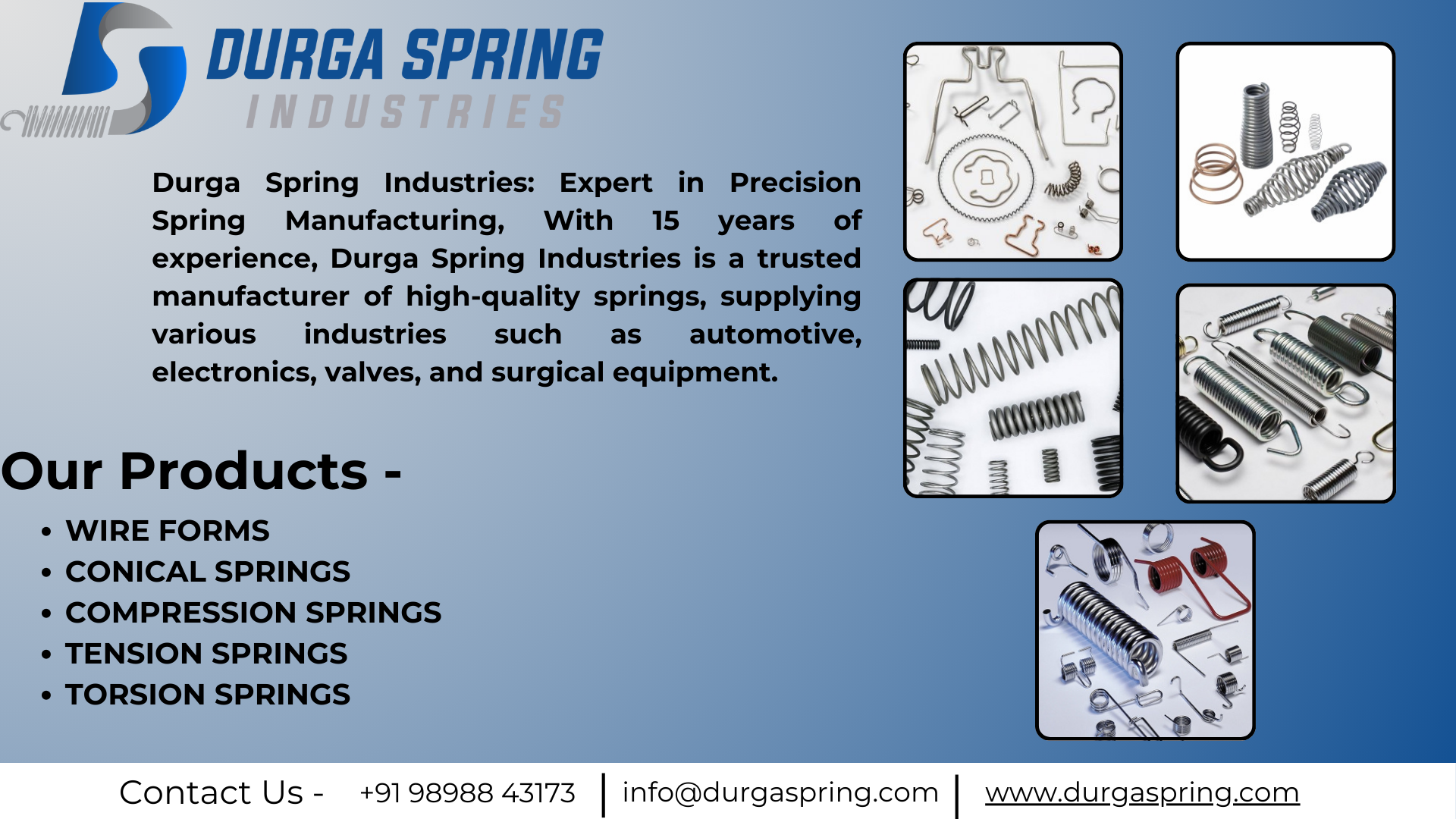

Compression Spring at Best Price in India

A Precise Compression Spring is a helical-shaped

mechanical component designed to resist axial compressive forces. It compresses

under load and returns to its original shape once the load is released,

providing accurate and repeatable force generation. Manufactured from

high-quality spring steel, stainless steel, or alloy materials, these springs

are crucial for energy absorption, shock resistance, and controlled movement in

machinery.

Whether for automotive, electronics, industrial machinery,

medical devices, or aerospace applications — precision compression springs

are custom-engineered to meet tight tolerances and performance standards. In

India, top manufacturers offer these springs in various sizes, wire diameters,

and load capacities at the most competitive prices for OEMs, exporters, and

industrial users.

Top 10

FAQs about Precise Compression Spring

Q1. What is a precise compression spring?

It is a coil spring designed to compress under load and exert a pushing force,

made to high-precision tolerances for consistent performance.

Q2. Where are compression springs used?

They’re used in automotive suspensions, valves, actuators, industrial

equipment, electrical switches, medical devices, and more.

Q3. What materials are used in manufacturing?

Common materials include high-carbon steel, stainless steel (SS304/316),phosphor bronze, and Inconel.

Q4. What sizes are available?

Sizes range from micro springs (less than 1 mm wire diameter) to heavy-duty

springs with larger diameters and lengths.

Q5. Can I get custom-designed springs?

Yes, manufacturers offer customization for dimensions, load rating, endtypes, and surface finish.

Q6. Are these springs corrosion-resistant?

Springs made from stainless steel or with surface coating (zinc, powder coat,

etc.) offer excellent corrosion resistance.

Q7. What is the spring index?

It is the ratio of coil diameter to wire diameter and affects the spring’s

performance and manufacturability.

Q8. Are compression springs reusable?

In many cases, yes — unless they’re overstressed or damaged during operation.

Q9. What is the load capacity of a compression spring?

It depends on the material, number of coils, diameter, and wire thickness —

ranges from a few grams to several tons.

Q10. Where can I find precise compression springs at the

best price in India?

From reliable OEMs, spring manufacturers, or industrial component suppliers

based in cities like Pune, Mumbai, Rajkot, Faridabad, and Coimbatore.

Key

Features of Precise Compression Spring with Uses

|

Feature |

Use / Benefit |

|

Accurate Force Tolerance |

Ensures precision performance in load-sensitive applications. |

|

Durable Spring Steel / SS |

Long-lasting material resists fatigue and corrosion. |

|

Wide Range of Sizes |

Suitable for micro-mechanisms to heavy industrial

machines. |

|

High Elastic Limit |

Capable of returning to shape after compression without

deformation. |

|

Custom End Configurations |

Closed ends, ground ends, or open ends to suit various

mounting needs. |

|

Surface Finishing Options |

Zinc plating, powder coating, and passivation for improved

life and hygiene. |

|

ISO / DIN Standards |

Manufactured to global standards for consistency and

compatibility. |

|

Compression Rate Control |

Designed to offer linear or progressive resistance based

on application. |

|

OEM Customization |

Branding, bulk packing, and engineering design for B2B

orders. |

|

Cost-effective in India |

High precision at low cost from Indian manufacturers for

global supply. |

Applications

of Precise Compression Spring

|

Industry |

Application |

|

Automotive |

Suspension systems, brakes, clutches, seat locks, fuel injection valves. |

|

Industrial Machinery |

Press tools, pumps, actuators, load cells, control

systems. |

|

Electronics |

Push buttons, connectors, battery holders, circuit

breakers. |

|

Medical Equipment |

Inhalers, surgical tools, diagnostic equipment. |

|

Aerospace |

High-performance, lightweight springs in flight and

control systems. |

|

Textile Machinery |

Tension control systems and mechanisms. |

|

Agricultural Equipment |

Seed drills, shock absorbers, and attachment systems. |

|

Consumer Goods |

Pens, toys, dispensers, door locks. |

|

Renewable Energy |

Mechanisms in solar tracking and wind turbine safety

locks. |

|

Packaging Industry |

Used in automatic sealing, strapping, and conveying

machines. |

Contact

Us For More Details On :

Call - +91 98988 43173

Email - info@durgaspring.com

Website –

www. durgaspring.com

YouTube -

www.youtube.com/@durgasprings

Facebook

- www.facebook.com/people/Durga-spring-industries

Filter Using Product Tags