Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

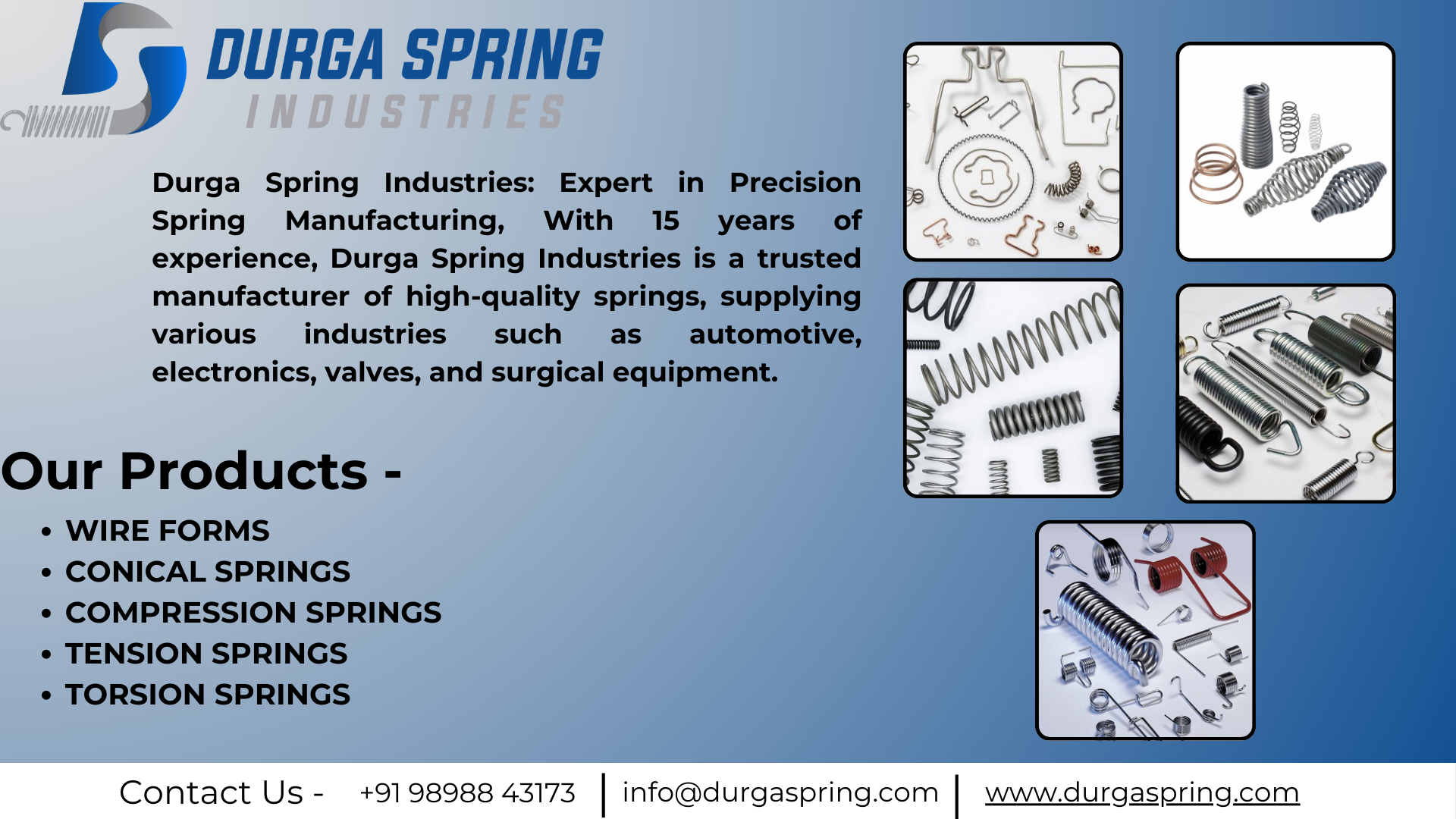

As a leading manufacturer of Custom Wire Forms in Ahmedabad, Durga Spring specializes in transforming client-specific designs into high-quality, precise metal components. We cater to the diverse manufacturing sector in Gujarat, providing tailor-made wire solutions for automotive, textile, electrical, and engineering applications. Our commitment to using advanced CNC wire bending services ensures that every custom component meets the tightest tolerances and specific functional requirements, solidifying our reputation as a trusted local industrial wire forms supplier in Gujarat.

Creating truly custom components requires a blend of skilled engineering and cutting-edge technology. Our process is streamlined for precision and efficiency:

For demanding projects requiring exact specifications, choosing the right manufacturer for your custom wire forms Ahmedabad is critical. Durga Spring offers not just manufacturing capability, but a partnership focused on delivering functional, reliable, and perfectly tailored metal components. We are strategically located in Ahmedabad to provide responsive service and streamlined communication throughout the design and production cycle. Contact us today to discuss your detailed drawings and requirement for bespoke wire components Ahmedabad.

Durga Spring• We’re here to help

Filter Using Product Tags