Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

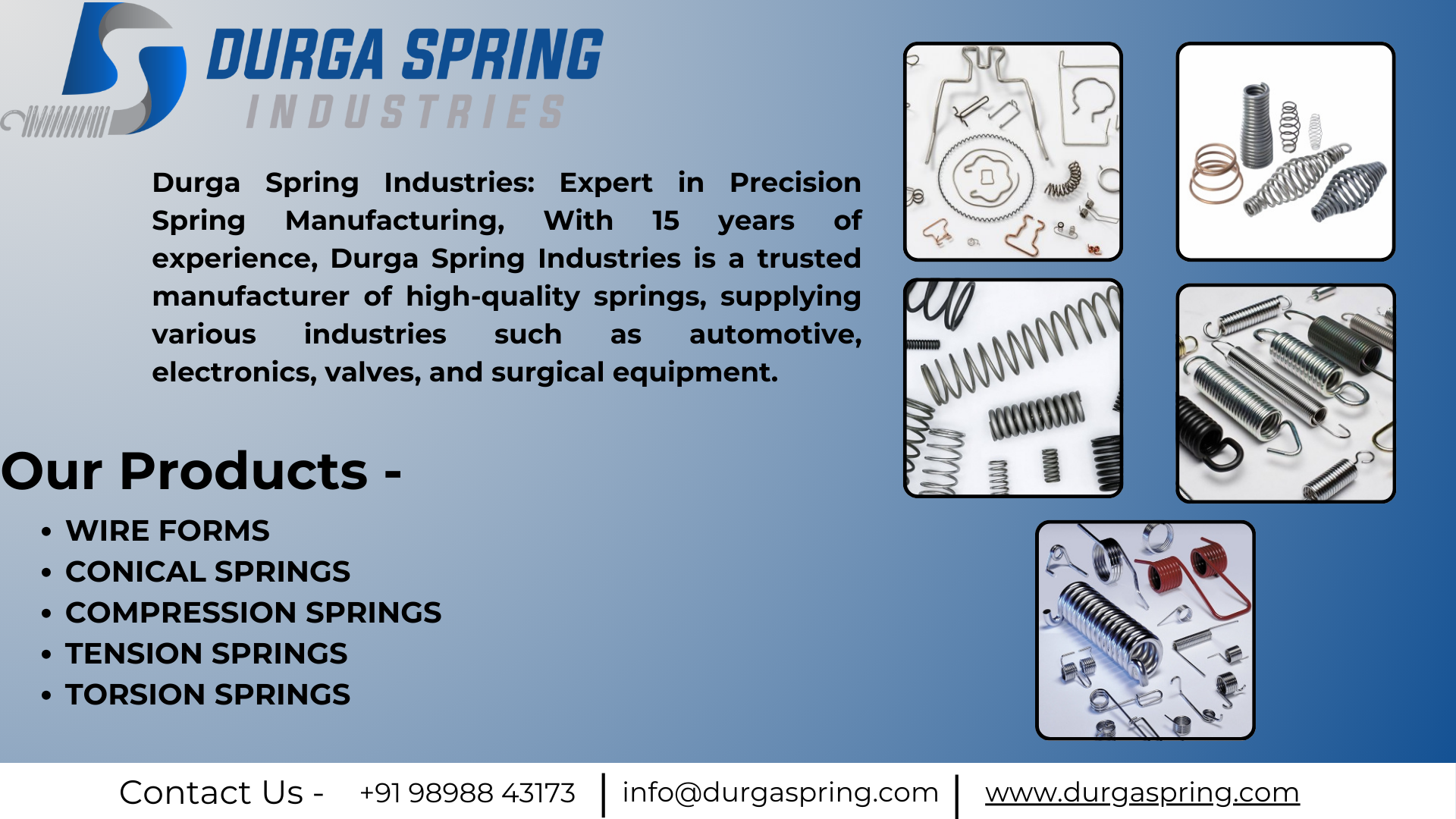

In precision engineering, the smallest component often carries the biggest responsibility. Durga Spring is a distinguished high-quality spring washer manufacturer in Ahmedabad, serving the robust industrial estates of Vatva, Naroda, and beyond with superior locking solutions. Our commitment to quality assurance goes beyond mere compliance; we ensure that every washer we produce—whether flat, square, or helical—provides consistent tension and zero-failure performance. By utilizing certified raw materials and advanced testing infrastructure, we deliver products that meet the stringent demands of automotive, electrical, and aerospace applications.

Delivering high-quality components requires a relentless focus on detail. We have integrated comprehensive quality checks at every stage of production to eliminate defects:

Durga Spring stands as a beacon of reliability for industries seeking a high-quality spring washer manufacturer in Ahmedabad. We understand that a single failed washer can lead to expensive downtime or safety hazards. Therefore, we do not compromise on our manufacturing standards. We invite technical directors and quality control managers to visit our facility or request samples. Experience the difference that precision engineering makes to your final product assembly with our certified, durable, and high-performance spring washers.

Durga Spring• We’re here to help

Filter Using Product Tags