Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

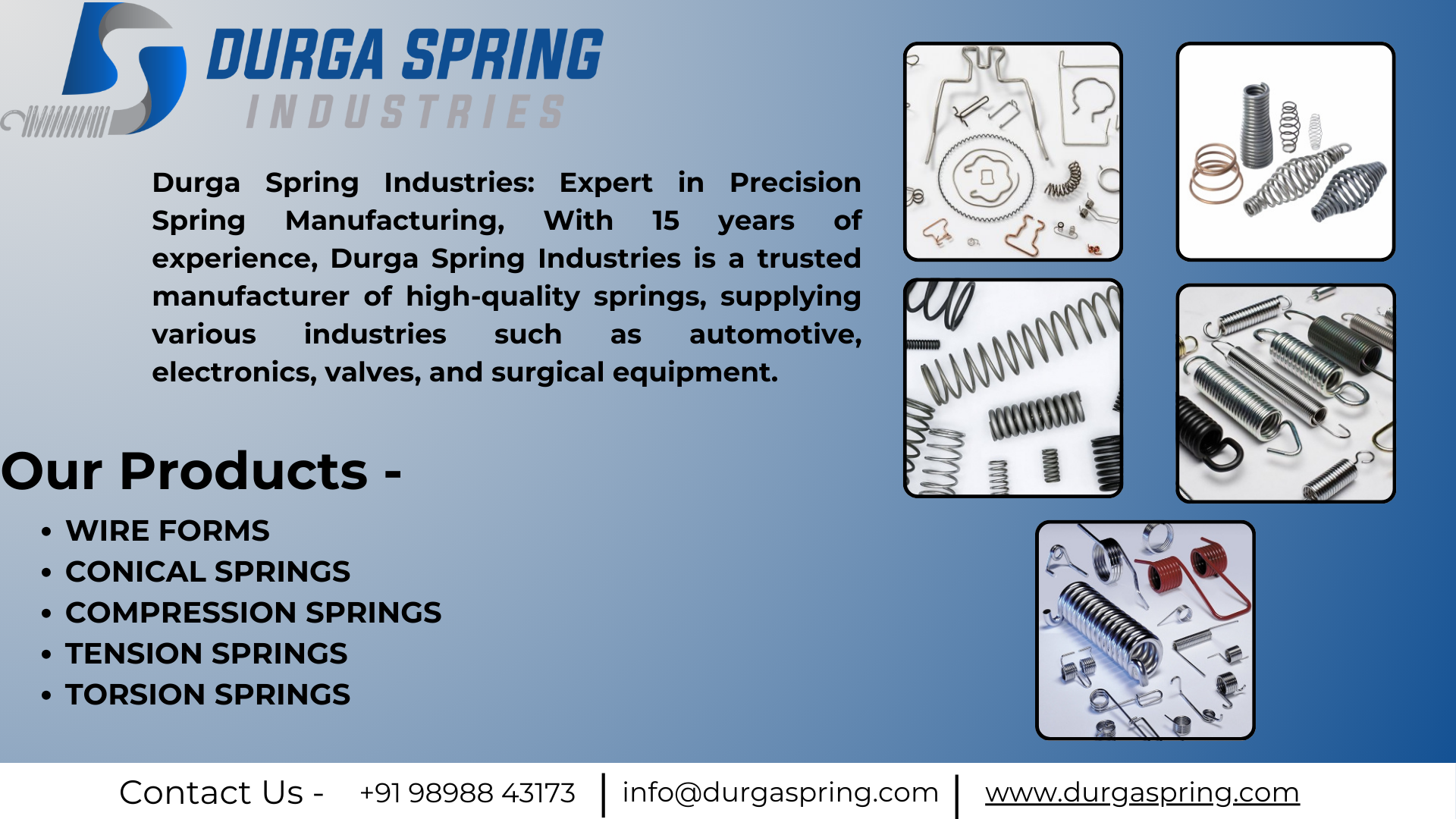

Durga Spring is committed to being one of the most affordable spiral spring manufacturers India has to offer, without compromising on functional quality or reliability. Based in Ahmedabad, Gujarat, we optimize our production processes to deliver cost-effective flat springs, power springs, and custom clock springs for bulk requirements across various industrial sectors. We provide a genuine value proposition, ensuring that affordability translates to long-term reliability for all our clients.

Our success as a **cost-effective flat spring supplier** is rooted in maximizing efficiency and minimizing waste. We utilize state-of-the-art machinery and bulk material sourcing to pass on significant savings to our customers. Key to our economical spring manufacturing India strategy are:

If you are seeking a trustworthy, **affordable spiral spring manufacturers India** partner, Durga Spring is your ideal choice. We specialize in working with businesses that require large quantities of springs with a demanding cost-to-performance ratio. By choosing us, you gain access to precision engineering that is scaled for affordability. Let us provide you with high-quality, **value engineered flat wire springs** that meet your technical needs and financial constraints.

Durga Spring• We’re here to help

Filter Using Product Tags