Best Torsion Spring Company in Ahmedabad

Best Torsion Spring Company in Ahmedabad

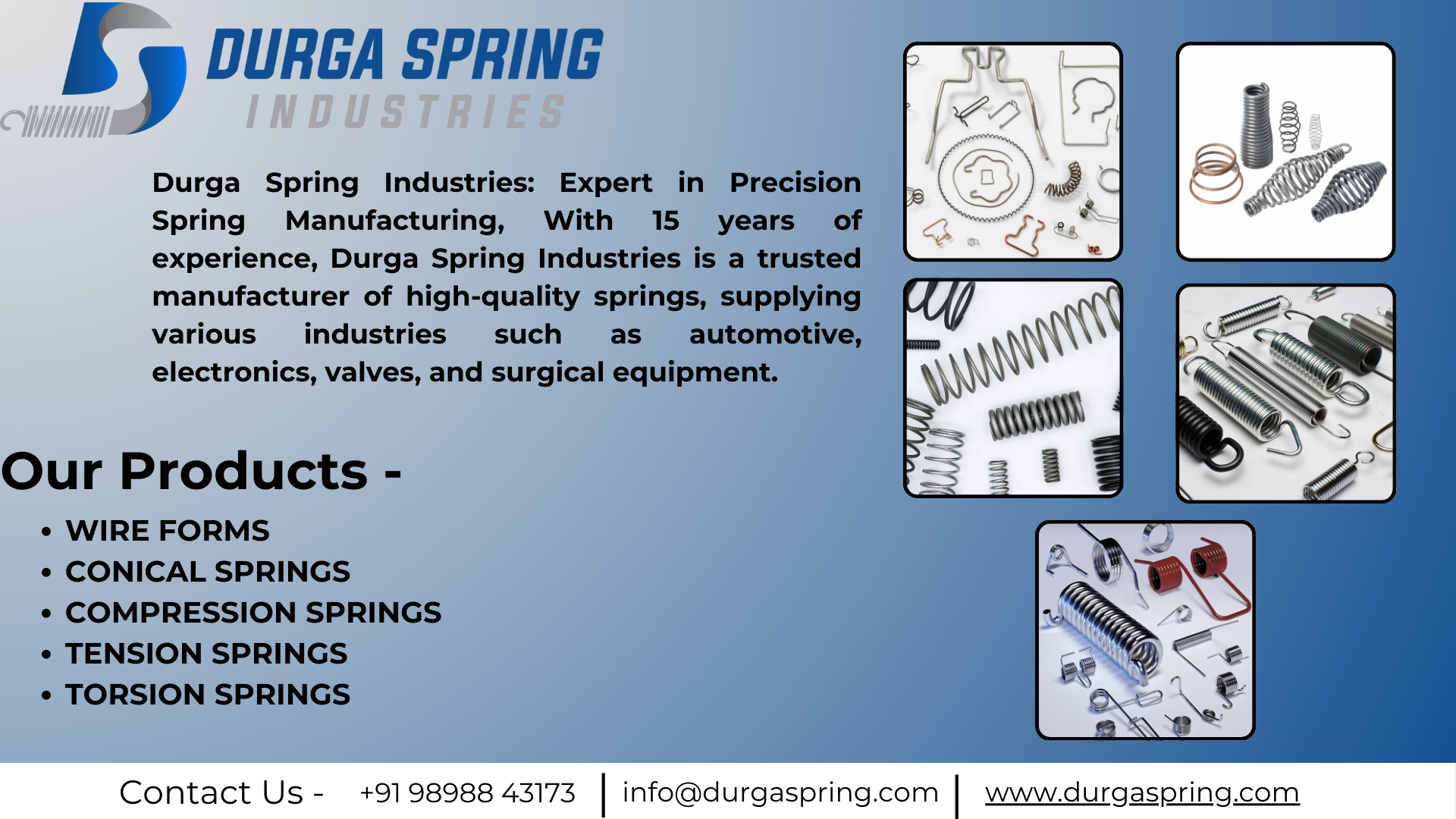

Description

As the best torsion spring company in Ahmedabad, we specialize in precision-engineered springs designed for durability, performance, and reliability. Our torsion springs are manufactured using premium-grade materials, ensuring optimal torque and long service life for various industrial and mechanical applications.

Applications and Benefits

Applications:

• Garage doors and shutter mechanisms

• Automotive and heavy vehicle components

• Industrial machinery and equipment

• Aerospace and defense assemblies

Benefits:

• High torque with minimal deformation

• Custom designs for specific load requirements

• Corrosion-resistant finishes available

• Long operational life with consistent performance

Key Features

• Manufactured using premium carbon and stainless steel

• Available in various diameters, lengths, and torque capacities

• Precision coiling for maximum accuracy

• Heat-treated for superior strength

• Designed to meet international

quality standards

Where It’s Used

• Industrial doors and gates

• Medical devices and equipment

• Aerospace control systems

• Agricultural machinery

Uses

• Energy storage in rotational mechanisms

• Controlled movement in assemblies

• Load balancing for heavy doors and systems

• Precision control in sensitive instruments

Importance and Significance

Torsion springs are critical components in countless mechanical systems, providing controlled torque and rotational force. Their design and manufacturing quality directly influence the safety, reliability, and efficiency of the equipment they power.

Why Choose Us

• Proven expertise in spring manufacturing

• Advanced machinery and skilled technicians

• Customized solutions for all industries

• Competitive pricing with reliable delivery

Manufacturer & Supplier in India

Durga Spring is a trusted name in Ahmedabad and across India for manufacturing and supplying high-quality torsion springs for diverse applications.

FAQs

What materials are used for your torsion springs?

We use high-grade carbon steel, stainless steel, and other alloys depending on application needs.Can you make custom torsion springs?

Yes, we design and manufacture springs to match exact torque, size, and material specifications.Do your springs meet industry standards?

Absolutely, all our springs comply with relevant industrial and international standards.What industries do you serve?

We supply to automotive, industrial, aerospace, agricultural, and commercial sectors.How can I order torsion springs?

Contact us with your specifications via our website or call us directly.

Conclusion

Choose Durga Spring for reliable, high-performance torsion springs in Ahmedabad—crafted to meet your exact requirements with precision and quality assurance.

Contact Information

Contact: +91 98988 43173

Email: info@durgaspring.com

Website: https://durgaspring.com/

Filter Using Product Tags