Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

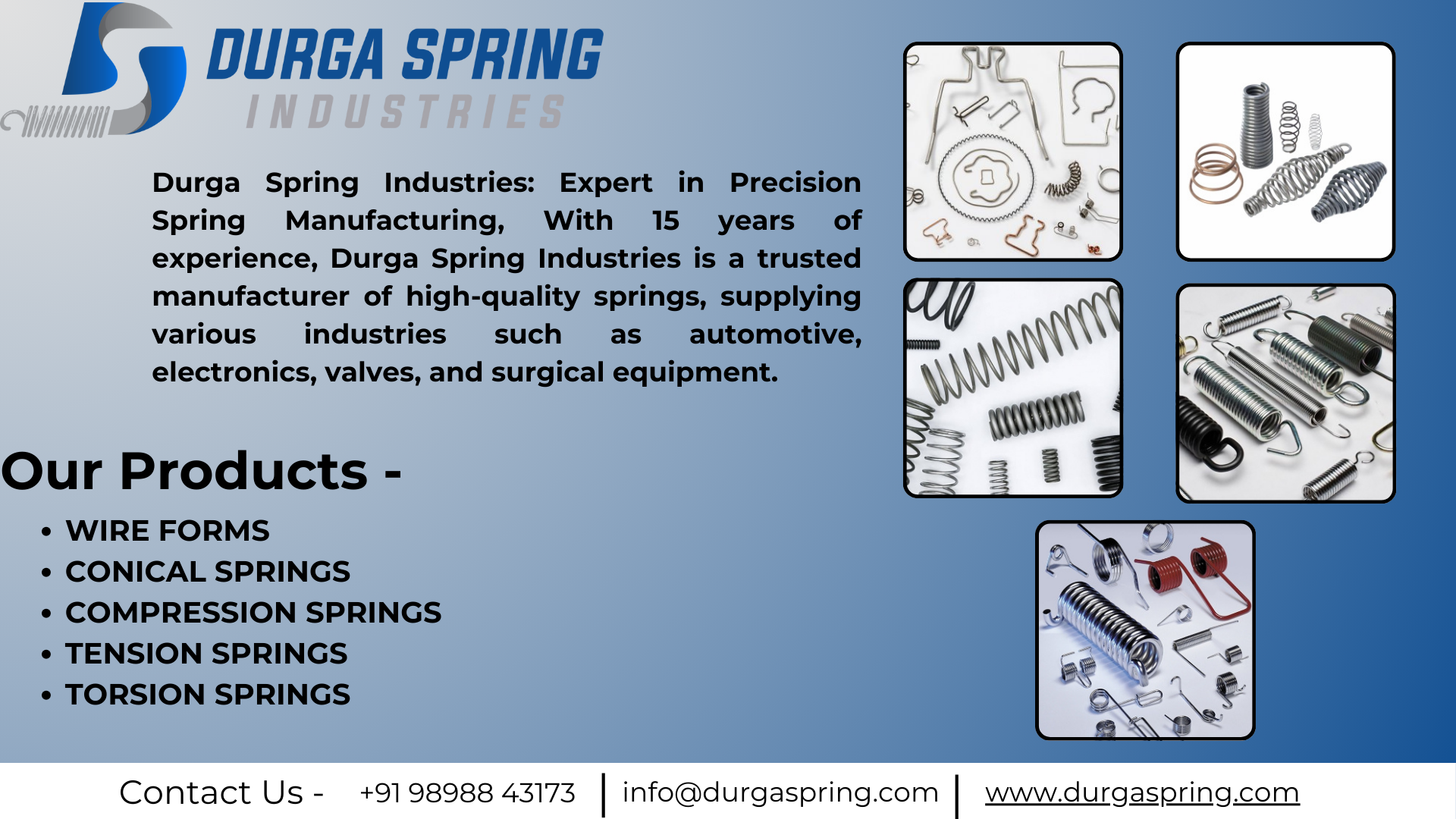

Choosing an Ahmedabad-based wire form supplier like Durga Spring Industries offers significant strategic advantages. Located in the heart of Gujarat's thriving industrial ecosystem, Ahmedabad provides access to a skilled workforce, superior raw materials, and robust logistical networks. An Ahmedabad-based supplier is ideally positioned to serve local industries with speed and efficiency while also catering to national demand. Wire forms are essential components in countless products, and partnering with a local expert ensures quick turnaround times, easier collaboration on custom designs, and responsive customer service. Durga Spring leverages these regional benefits to deliver precision-engineered wire forms for automotive, electrical, and industrial applications.

The manufacturing strength of an Ahmedabad-based wire form supplier lies in its adoption of modern technology combined with meticulous craftsmanship. At Durga Spring, our state-of-the-art facility is equipped with advanced CNC wire forming machines that guarantee high precision and consistency for every component. The process begins with sourcing premium-grade wire, followed by automated bending, cutting, and shaping according to exact client specifications. Our proximity to ancillary service providers in Ahmedabad allows for efficient completion of secondary processes like heat treatment, plating, and coating. This integrated approach ensures we deliver top-quality, durable wire forms that meet the highest industry standards.

For businesses operating in Gujarat and Western India, having an Ahmedabad-based wire form supplier is an invaluable asset. Durga Spring Industries is more than just a vendor; we are a local partner dedicated to your success. We provide the reliability and advanced capabilities of a national manufacturer with the personalized service and accessibility of a regional specialist. Our team is always available to discuss your specific needs and provide tailored solutions that enhance your products and streamline your supply chain. Trust a local leader to deliver the precision and quality your business deserves.

Durga Spring• We’re here to help

Filter Using Product Tags