Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

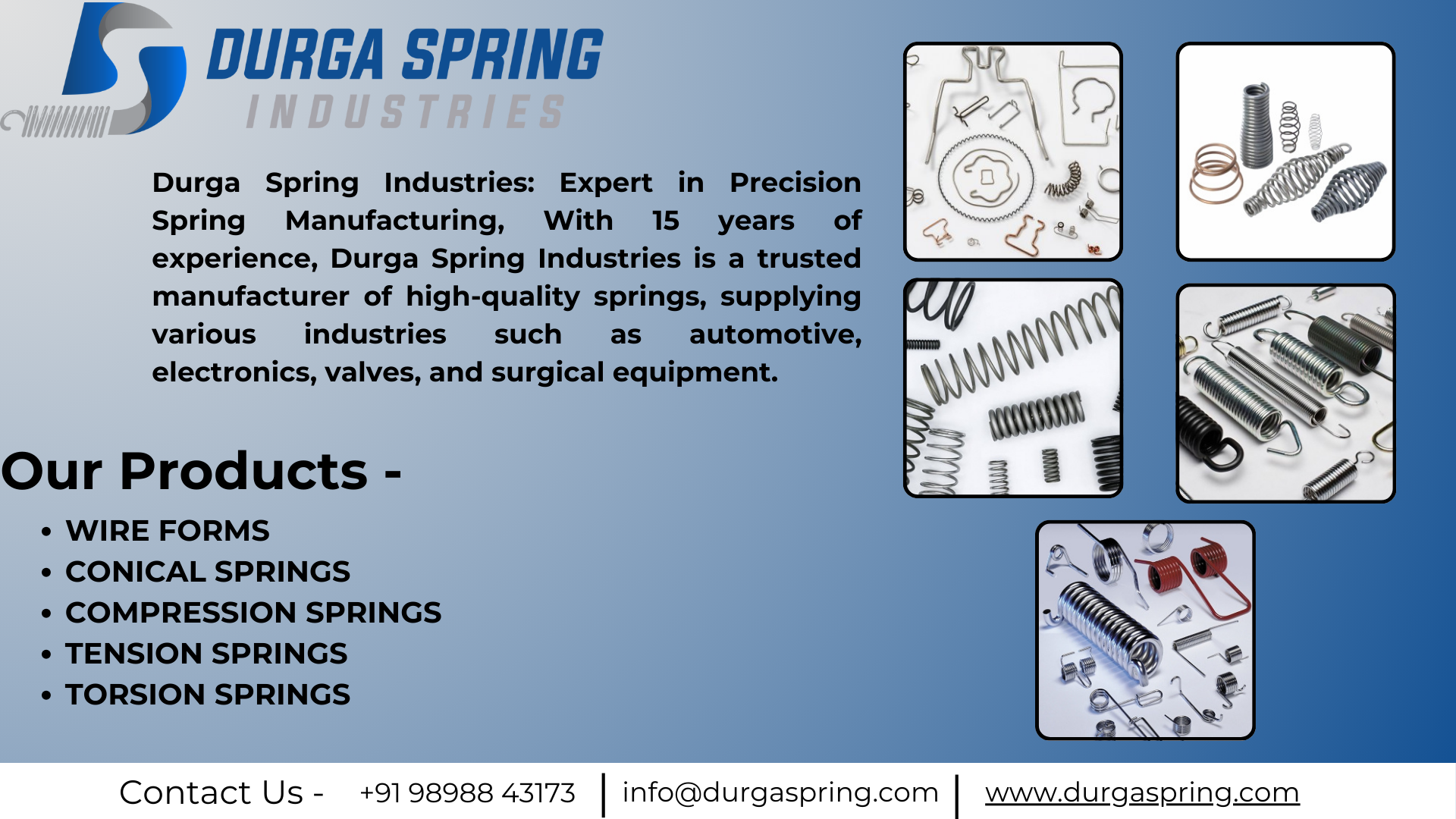

Gujarat’s industrial landscape demands reliable fastening solutions, making the choice of **best spring washer suppliers in Gujarat** critical. Durga Spring stands out as a manufacturer and supplier committed to precision engineering. We specialize in producing a diverse range of spring washers—including **split spring washer supplier Gujarat** relies on, helical lock washers, and conical washers—all designed to maintain tight bolt tension and prevent loosening caused by vibration and thermal cycling across diverse heavy industries and OEM applications.

Our reputation as a **leading spring washer manufacturer** in the region is built on unwavering quality and robust supply chain management.

As one of the **best spring washer suppliers in Gujarat**, we prioritize logistics and customer service. Our central location in Ahmedabad allows for efficient distribution channels, minimizing lead times for our clients across Vadodara, Surat, Rajkot, and Kutch. Whether you require standard DIN 127 helical washers or specialized washers for high-stress environments, Durga Spring is your trusted partner for **high quality spring washers India**'s industries rely on. Partner with us for a stable and certified supply of all your industrial fastener needs.

Durga Spring• We’re here to help

Filter Using Product Tags