Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

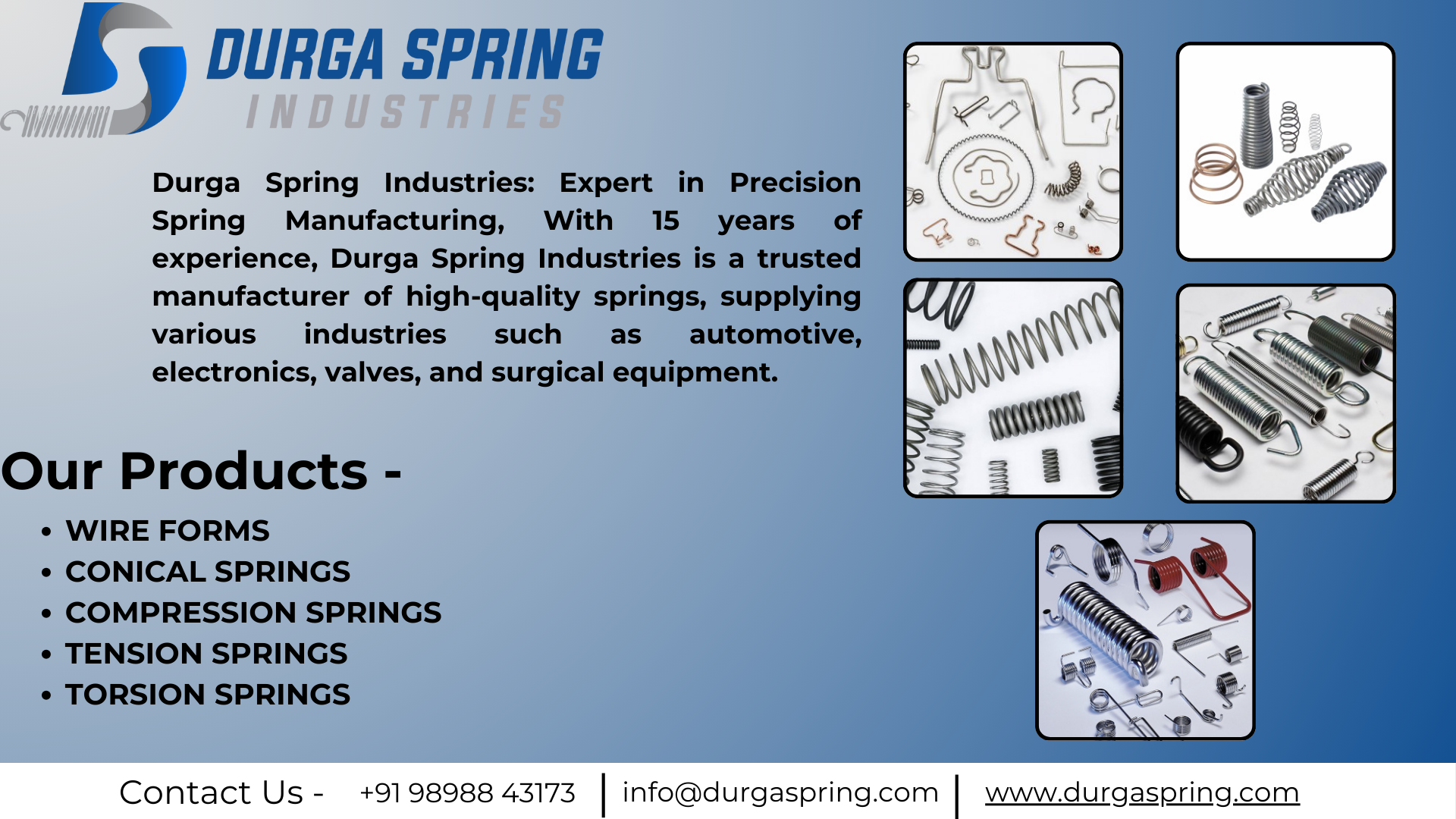

Torsion

Springs Price & Details

Torsion springs are helical springs that work by twisting

their ends along the axis to exert torque or rotational force. These

springs are commonly used in applications that require angular motion,

such as garage doors, clothespins, levers, hinges, and machinery.

The price of torsion springs depends on various

factors including material (stainless steel, carbon steel, phosphor bronze),

coil diameter, wire diameter, number of coils, torque rating, and custom

requirements. Prices in India typically range from ?5 to ?500 per piece,

with custom industrial torsion springs priced higher depending on load and

durability specifications.

Applications

of Torsion Springs

|

Industry |

Application |

|

Automotive |

Car trunk hinges, throttle control systems, and gear assemblies |

Aerospace |

Control surface actuation, retractable systems |

|

Home Appliances |

Washing machines, cloth dryers, and oven doors |

|

Industrial Equipment |

Latching mechanisms, switchgear, and rotating systems |

|

Garage Doors |

Opening/closing door mechanisms with counterbalancing

torque |

|

Furniture |

Recliners, foldable chairs, and mechanisms in beds |

|

Medical Devices |

Surgical tools and mechanical drug dispensers |

|

Consumer Goods |

Clothespins, clipboards, latches, and toys |

Features

with Uses of Torsion Springs

|

Feature |

Description |

Use / Benefit |

|

High Torque Output |

Converts twist into torque |

Used in rotating or counterbalancing mechanical systems |

|

Direction Specific (RH/LH) |

Available in right-hand and left-hand windings |

Matches rotation direction of specific applications |

|

Material Variety |

Stainless steel, music wire, carbon steel, phosphor bronze |

For corrosion resistance, high fatigue life, or electrical

use |

|

Leg Configurations |

Straight, hook, loop, or custom leg designs |

Tailored for fitment and motion control |

|

Compact Design |

Requires minimal space while delivering high energy

storage |

Ideal for tight mechanical enclosures |

|

Durability |

Designed for high cycle life |

Long-term use in repetitive motion systems |

|

Custom Load & Angle Settings |

Manufactured for specific torque and angular deflection |

Provides precise control over motion |

|

Double Torsion Option |

Two coils wound in opposite directions for double torque |

Common in high-load symmetrical applications |

|

RoHS & REACH Compliant |

Available for electronics and export-grade needs |

Ensures environmental and safety compliance |

|

OEM/Custom Engineering |

Springs can be designed for any prototype or machine

requirement |

Enhances fitment and functionality in specialized

applications |

Torsion

Spring Pricing in India (Indicative Range)

|

Type |

Size / Spec |

Approx. Price (INR) |

|

Small torsion spring (SS wire) |

1 mm, 5 coils |

5 – 20/piece |

|

Medium spring (MS wire, zinc coated) |

2 mm, 8 coils, 90° deflection |

20 – 80/piece |

|

Heavy-duty garage door torsion spring |

3-6 mm, 200-300 mm length |

150 – 500/piece |

|

Industrial customized torsion spring |

Custom size, 20+ Nm torque |

500 – 2000/piece |

|

Bulk order (1000+ pcs) |

Small to mid-size |

Negotiable (3 – 50/pc) |

Key

Points on Torsion Spring Purchase & Selection

Top 10

FAQs on Torsion Springs & Pricing

Contact

Us For More Details On :

Call - +91 98988 43173

Email - info@durgaspring.com

Website –

www. durgaspring.com

YouTube -

www.youtube.com/@durgasprings

Facebook

- www.facebook.com/people/Durga-spring-industries

Filter Using Product Tags