Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Electrical

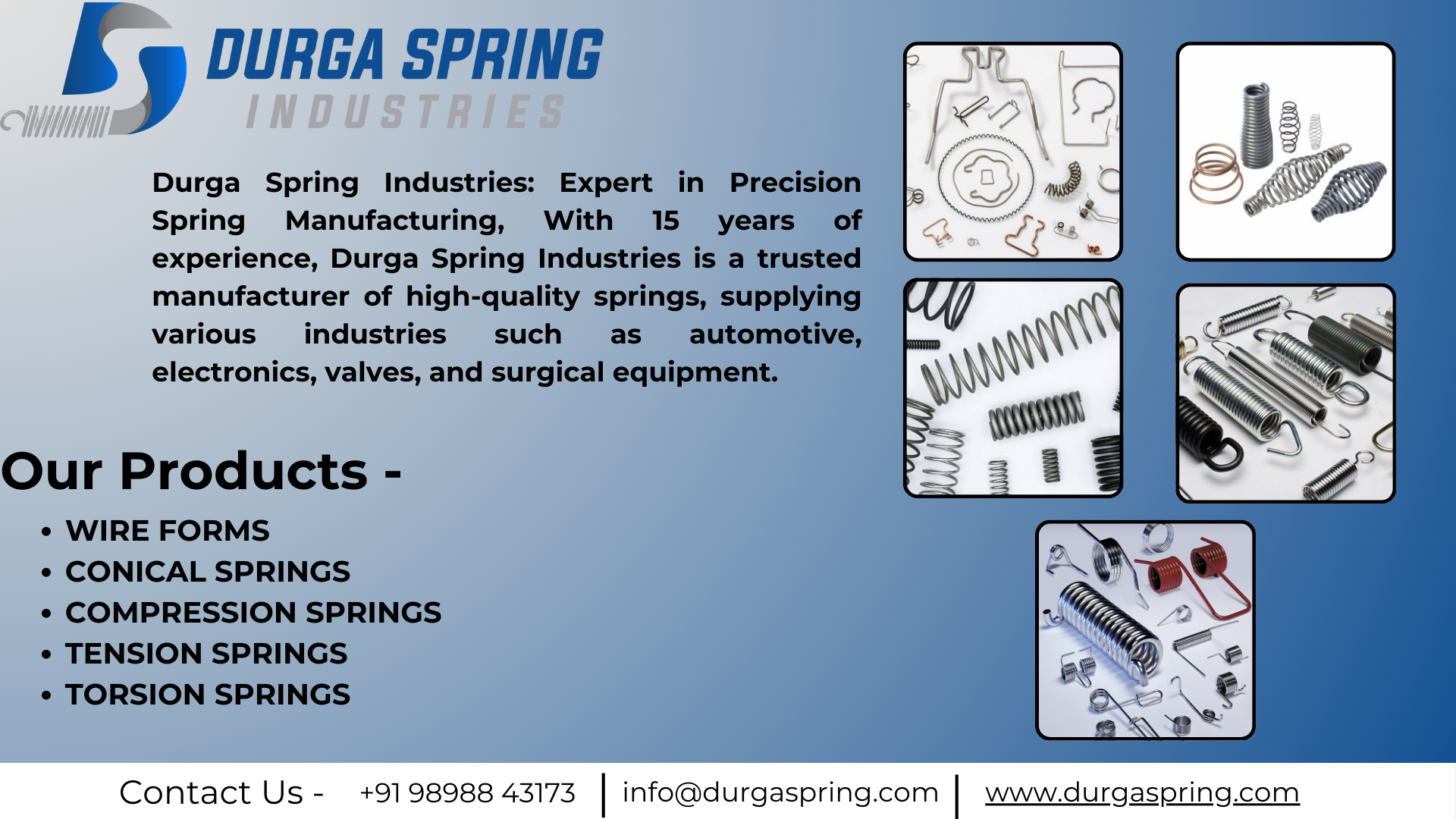

Wire Forms

Electrical Wire Forms are precisely shaped metal

wires used in electrical and electronic assemblies to create mechanical

supports, electrical contacts, terminals, grounding paths, or conductive routes

within devices or systems. Made from conductive metals like copper,

brass, stainless steel, and beryllium copper, these wire forms are custom-bent

into 2D or 3D geometries using CNC wire forming machines or manual processes.

These components are vital in industries such as automotive,telecommunications, consumer electronics, switchgear systems, lighting, andcontrol panels—offering durability, electrical conductivity, and shape

stability. Electrical wire forms can also include spring-type connectors,

clips, brackets, and contact arms, enabling them to serve

mechanical and electrical purposes simultaneously.

Key

Features & Their Uses

|

Feature |

Use / Benefit |

|

Custom 2D & 3D Shapes |

Tailored to fit specific electrical or mechanical assemblies. |

High Conductivity Metals |

Ensures efficient current flow in circuits or ground

paths. |

|

Springback & Flexibility |

Ideal for clips, terminals, and battery contacts. |

|

Corrosion-Resistant Finishes |

Enhances durability in harsh or outdoor environments. |

|

Precision CNC Wire Bending |

Guarantees consistency and tight tolerances for mass

production. |

|

Small to Large Wire Diameters |

Suits low-voltage electronics or heavy-duty industrial

components. |

|

Plating Options (Tin, Nickel, etc.) |

Improves electrical performance and prevents oxidation. |

|

Mechanical Strength |

Provides structural support in assemblies without welding. |

|

UL & RoHS Compliance (optional) |

Ensures safety and environmental compliance in global

markets. |

|

Fast Prototyping & Custom Tooling |

Enables quick development of application-specific wire

forms. |

Applications

of Electrical Wire Forms

Top 10

FAQs – Electrical Wire Forms

1. What materials are commonly used for electrical wire

forms?

Copper, brass, phosphor bronze, stainless steel, and beryllium copper are mostcommonly used.

2. What industries use wire forms?

Automotive, consumer electronics, switchgear, aerospace, telecom, and appliance

manufacturing.

3. Can wire forms carry electrical current?

Yes, many are designed to conduct current—especially when used as contacts,

terminals, or ground paths.

4. What size range is available for electrical wire

forms?

Typically from 0.3 mm to 8 mm wire diameter, but larger sizes are also

possible for heavy-duty applications.

5. Are wire forms available with insulation?

Yes, insulated or coated wire forms can be made, depending on the application

requirements.

6. How accurate are CNC-formed wire components?

Very precise, with tolerances typically within ±0.1 mm for consistent

fit and function.

7. Are these forms reusable or permanent?

Some are reusable (like spring contacts), while others are fixed components in

assemblies.

8. Can I request a custom wire form for my design?

Yes, manufacturers offer custom designs with prototyping, tooling, and

engineering support.

9. Do wire forms require surface treatment?

Yes, depending on the environment, they may be tin-plated, nickel-plated, or

passivated.

10. What is the lead time for production?

Typically 2 to 4 weeks for custom wire forms, depending on complexity

and quantity.

Contact

Us For More Details On :

Call - +91 98988 43173

Email - info@durgaspring.com

Website –

www. durgaspring.com

YouTube -

www.youtube.com/@durgasprings

Facebook

- www.facebook.com/people/Durga-spring-industries

Filter Using Product Tags