Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

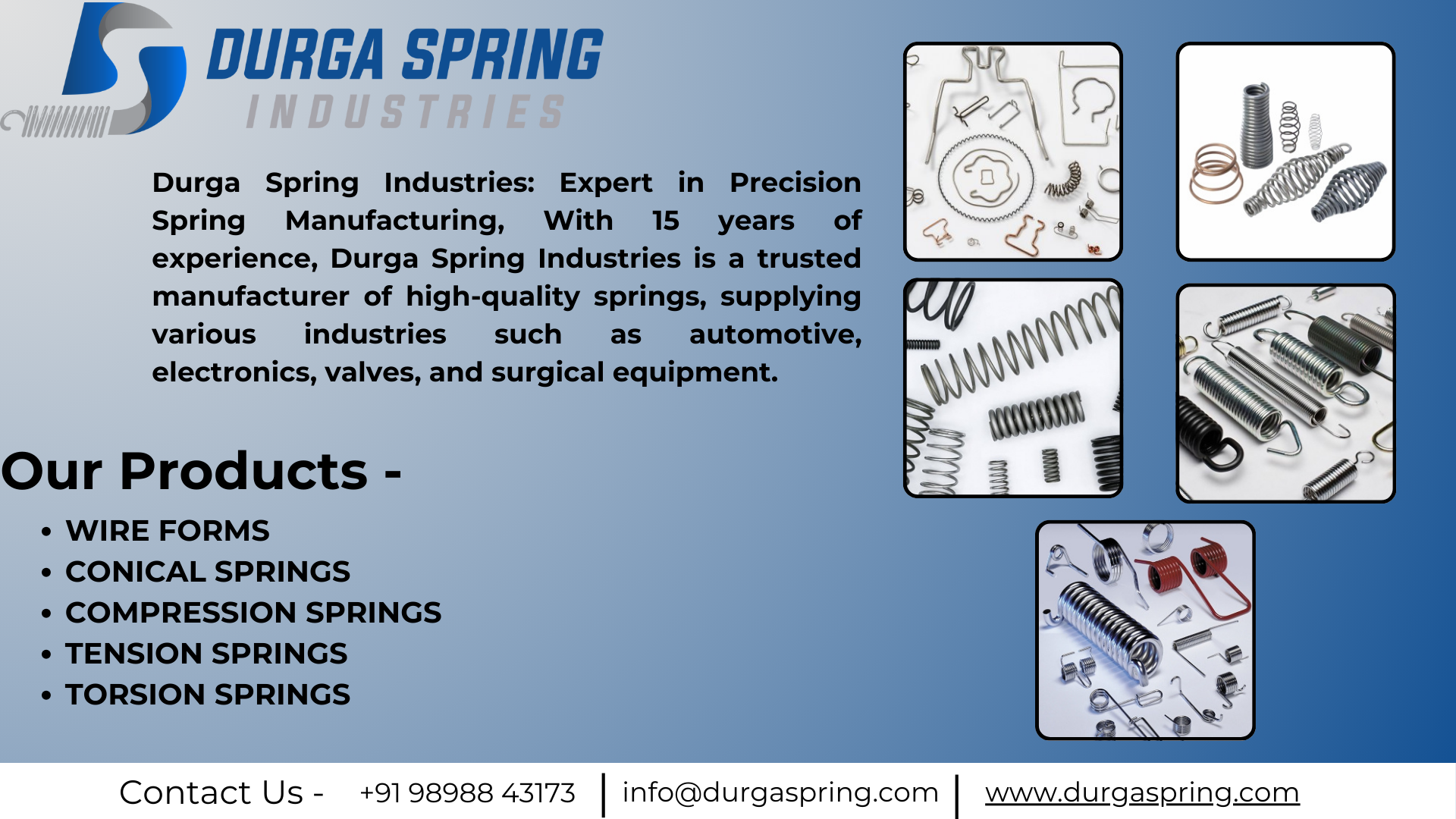

Wire

Forms at Best Price in India

Description:

Wire Forms are custom-shaped wires manufactured

through processes like bending, coiling, and cutting to meet specific

mechanical, structural, or decorative needs. They are made from materials such

as stainless steel, carbon steel, spring steel, copper, and brass, depending on

the application requirements.

Wire Form manufacturers in India offer

high-precision, durable, and cost-effective solutions for a wide range of

industries including automotive, electronics, appliances, medical devices,

construction, and general industrial applications. Whether it’s compression

wire forms, extension shapes, clips, hooks, rings, or specialty configurations,

buyers in India can find premium quality products at the best price without

compromising on performance.

Top 10

FAQs About Wire Forms at Best Price in India:

1. What is a wire form?

A wire form is a wire that has been bent, shaped, or twisted into a specific

configuration to serve a mechanical or functional purpose.

2. What materials are commonly used for wire forms?

Stainless steel, carbon steel, spring steel, copper, brass, and sometimes

titanium for specialized applications.

3. How are wire forms manufactured?

Wire forms are produced using CNC wire forming machines, manual bending,

coiling, stamping, and welding depending on the complexity.

4. Can wire forms be customized?

Yes, wire forms are highly customizable in size, shape, diameter, and finish

based on customer specifications.

5. What industries typically use wire forms?

Automotive, medical, electronics, furniture, agricultural equipment, and

construction industries.

6. What finishing options are available for wire forms?

Electroplating, powder coating, galvanizing, anodizing, and passivation for

enhanced corrosion resistance and appearance.

7. Are wire forms corrosion-resistant?

Depending on the material and finishing, wire forms can be highly

corrosion-resistant (especially stainless steel or galvanized finishes).

8. What wire diameters are available?

Manufacturers offer a wide range, usually from 0.2 mm to 20 mm or larger,

depending on application needs.

9. What is the production capacity for bulk orders?

Many Indian manufacturers can produce hundreds of thousands of wire forms per

month for large industrial requirements.

10. How is pricing determined for wire forms in India?

Pricing is based on material type, complexity of design, size, volume ordered,

and surface treatment.

Applications

of Wire Forms:

Features

and Their Uses:

|

Feature |

Use |

|

Custom Shape Capability |

Designs wire forms precisely for unique applications in any industry. |

Wide Material Choice |

Ensures compatibility with different environments (e.g.,

corrosion-prone, high-load). |

|

Precision Manufacturing |

Provides dimensional accuracy, essential for mechanical

assemblies. |

|

Corrosion Resistance (with Finishing) |

Extends lifespan of wire forms exposed to moisture and

chemicals. |

|

Durability and High Tensile Strength |

Suitable for load-bearing and high-stress environments. |

|

Flexibility in Design |

Allows complex 2D and 3D wire forms with tight tolerances. |

|

Lightweight yet Strong |

Provides structural support without excessive weight. |

|

Cost-Effectiveness |

Offers economical solutions for mass production and

replacements. |

|

Easy to Assemble |

Facilitates quick integration into larger assemblies and

products. |

|

Eco-Friendly Material Options |

Many wire forms are recyclable, supporting sustainability

efforts. |

Contact

Us For More Details On :

Call - +91 98988 43173

Email - info@durgaspring.com

Website –

www. durgaspring.com

YouTube -

www.youtube.com/@durgasprings

Facebook

- www.facebook.com/people/Durga-spring-industries

Filter Using Product Tags