Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

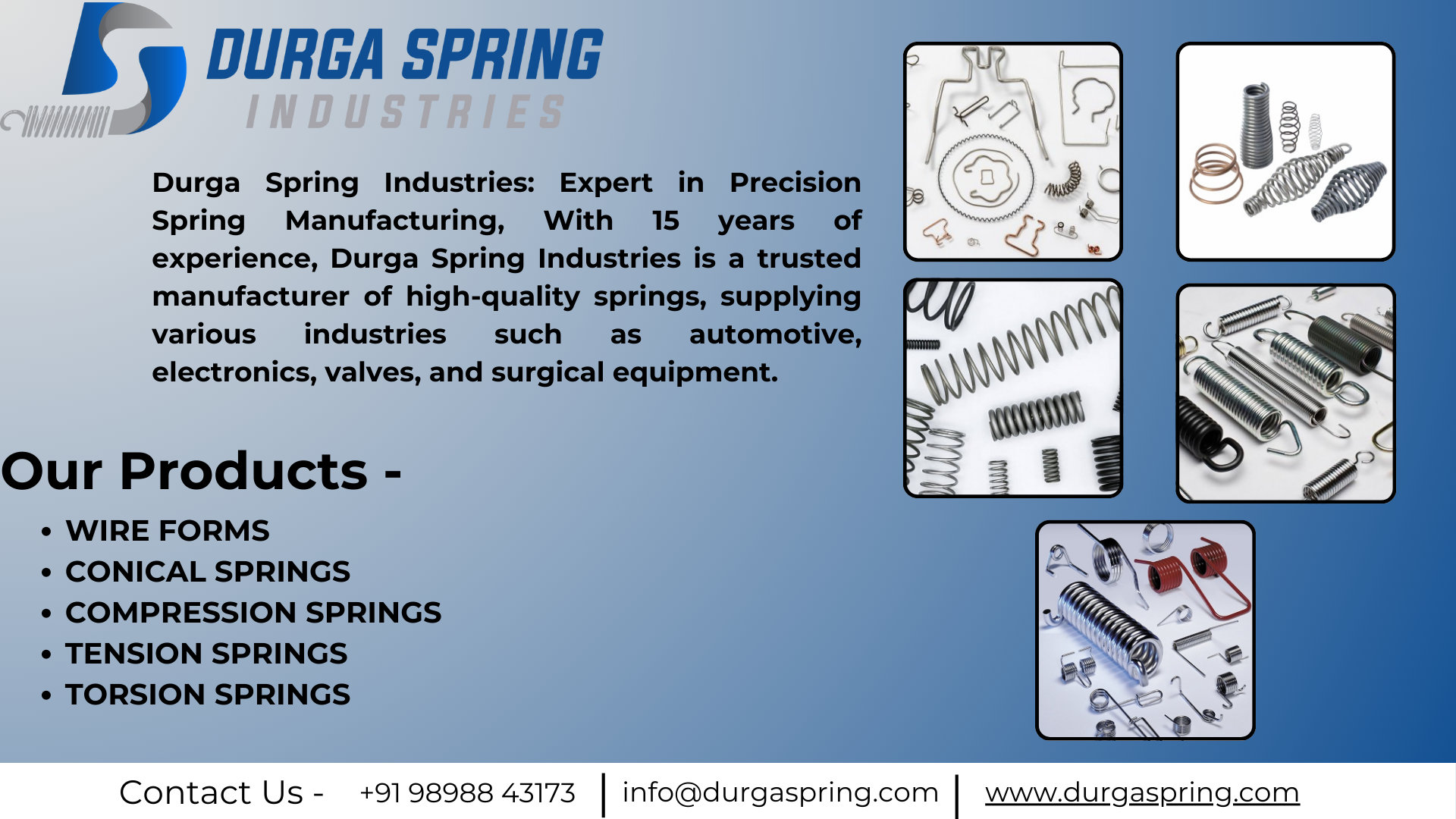

As a prominent **Conical Spring Manufacturer in Ahmedabad**, Durga Spring offers specialized manufacturing of high-quality **tapered compression springs**. These unique springs are designed to occupy minimal solid height and provide a progressive resistance rate, making them ideal for applications requiring stable, controlled energy storage and dissipation. Serving the industrial and automotive hubs of Ahmedabad and the wider Gujarat region, we utilize advanced CNC coiling machinery to ensure every conical spring meets exact specifications regarding pitch, taper, and material composition (e.g., spring steel, stainless steel, chrome silicon).

The complexity of producing **conical springs** necessitates precision engineering. Our Ahmedabad facility is equipped for the challenge, focusing on critical aspects of production:

For procurement professionals and design engineers seeking a dependable **Conical Spring Manufacturer in Ahmedabad**, Durga Spring offers unparalleled technical support and manufacturing capacity. We pride ourselves on converting complex design requirements into reliably performing components. Our commitment to quality, punctual delivery, and technical excellence ensures that our **tapered compression springs** integrate seamlessly into your most demanding assemblies. Contact us today to discuss your spring design and volume needs across Gujarat.

Durga Spring• We’re here to help

Filter Using Product Tags