Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Spiral

Springs

Best

Description of Spiral Springs

Spiral Springs, also known as flat coil springs

or clock springs, are mechanical devices made from flat strips of

high-tensile spring steel wound tightly in a spiral or helical shape. These

springs are designed to store and release rotational energy, making them

essential in applications that require torque and angular deflection. Spiral

springs are compact, reliable, and capable of delivering consistent torque in a

small footprint. Widely used in automotive components, electrical devices,

mechanical assemblies, and industrial machinery, spiral springs are valued for

their precision, repeatability, and long fatigue life.

Key

Features of Spiral Springs

Applications

of Spiral Springs

Uses of

Spiral Springs

Top 10

FAQs on Spiral Springs

1. What is a spiral spring?

A spiral spring is a flat strip of metal wound into a coil that stores and

releases rotational energy.

2. What materials are used for spiral springs?

High-carbon spring steel, stainless steel, beryllium copper, and Inconel are

commonly used.

3. How does a spiral spring work?

It operates by winding and unwinding to provide torque or angular displacement.

4. What is the difference between a spiral spring and a

torsion spring?

While both deal with torque, spiral springs use flat material wound in a

spiral, whereas torsion springs use round wire wound in a helix.

5. Where are spiral springs used?

In automotive systems, clocks, retractable devices, industrial machinery, and

more.

6. Can spiral springs be customized?

Yes, manufacturers can customize size, torque, number of turns, material, and

finish.

7. How long does a spiral spring last?

With proper design and application, they can last for thousands to millions of

cycles.

8. Are spiral springs corrosion-resistant?

Yes, if made from stainless steel or coated appropriately.

9. What are the load capabilities of spiral springs?

It depends on design parameters like material, width, thickness, and coil

count.

10. Can spiral springs be used in high-temperature

environments?

Yes, with materials like Inconel or heat-treated steel for thermal resistance.

Contact

Us For More Details On :

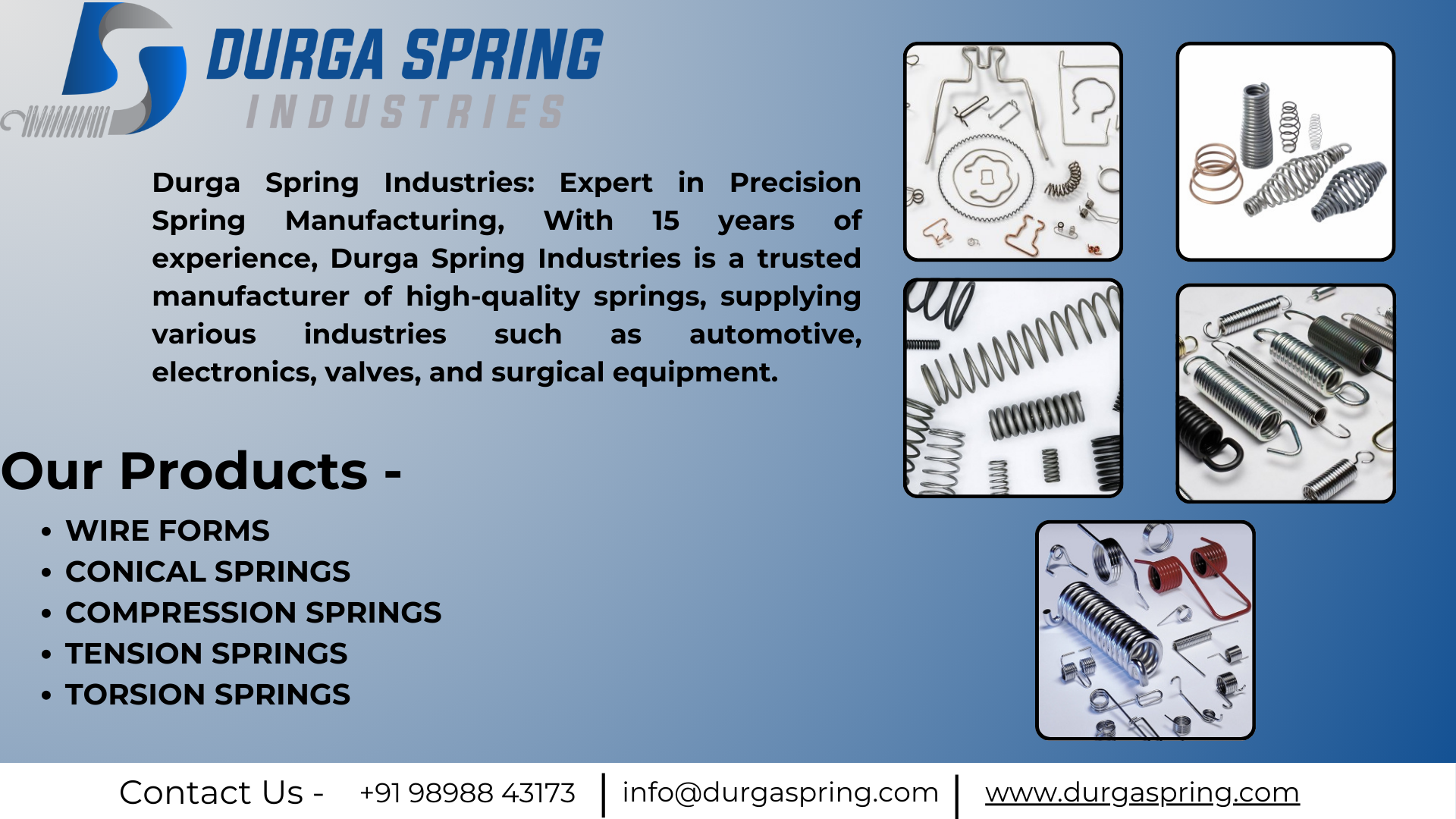

Call - +91 98988 43173

Email - info@durgaspring.com

Website –

www. durgaspring.com

YouTube -

www.youtube.com/@durgasprings

Facebook

- www.facebook.com/people/Durga-spring-industries

Filter Using Product Tags