Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

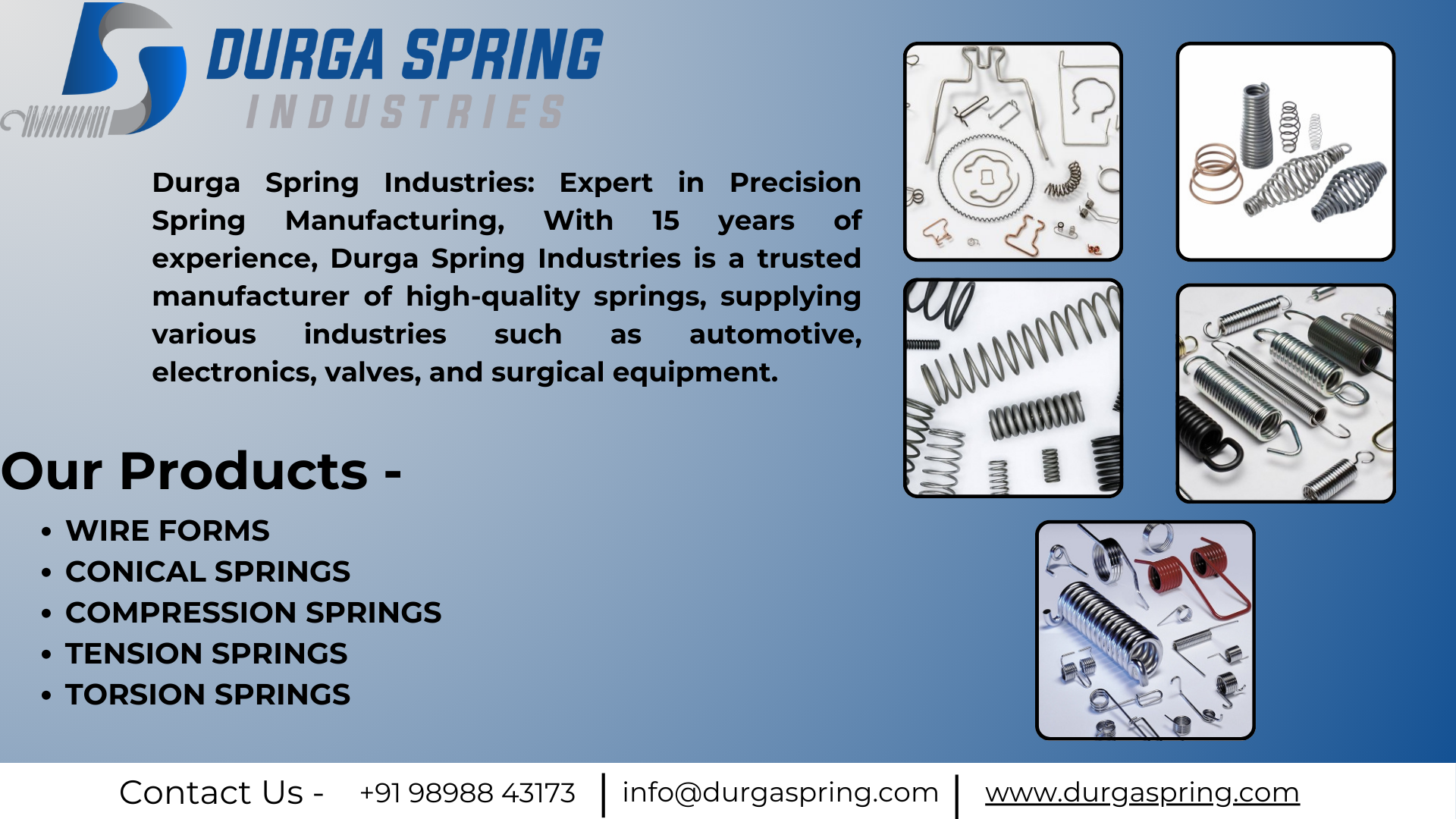

Durga Spring stands as a premier Industrial Spiral Spring Manufacturer in India, specializing in the production of high-performance flat spiral, power, and constant force springs crucial for heavy machinery, automotive components, and large-scale industrial equipment. Our manufacturing facility utilizes state-of-the-art coiling technology and robust quality control systems to ensure every spring delivers exceptional torque, fatigue life, and reliability under rigorous operational stresses. We are dedicated to providing the Indian industrial sector with customized, durable spring solutions that meet or exceed global standards.

Our strength in Custom Power Spring Production India lies in our ability to engineer springs that withstand extreme industrial conditions:

As a leading Industrial Spiral Spring Manufacturer in India, Durga Spring understands the non-negotiable need for reliability and durability in industrial environments. We do not compromise on the quality of materials or the precision of our engineering, ensuring that our springs perform flawlessly even under heavy loads and continuous operation. If your machinery requires Heavy Duty Flat Spiral Springs or custom power solutions, partner with us to guarantee long-term performance and robust component supply.

Durga Spring• We’re here to help

Filter Using Product Tags