Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

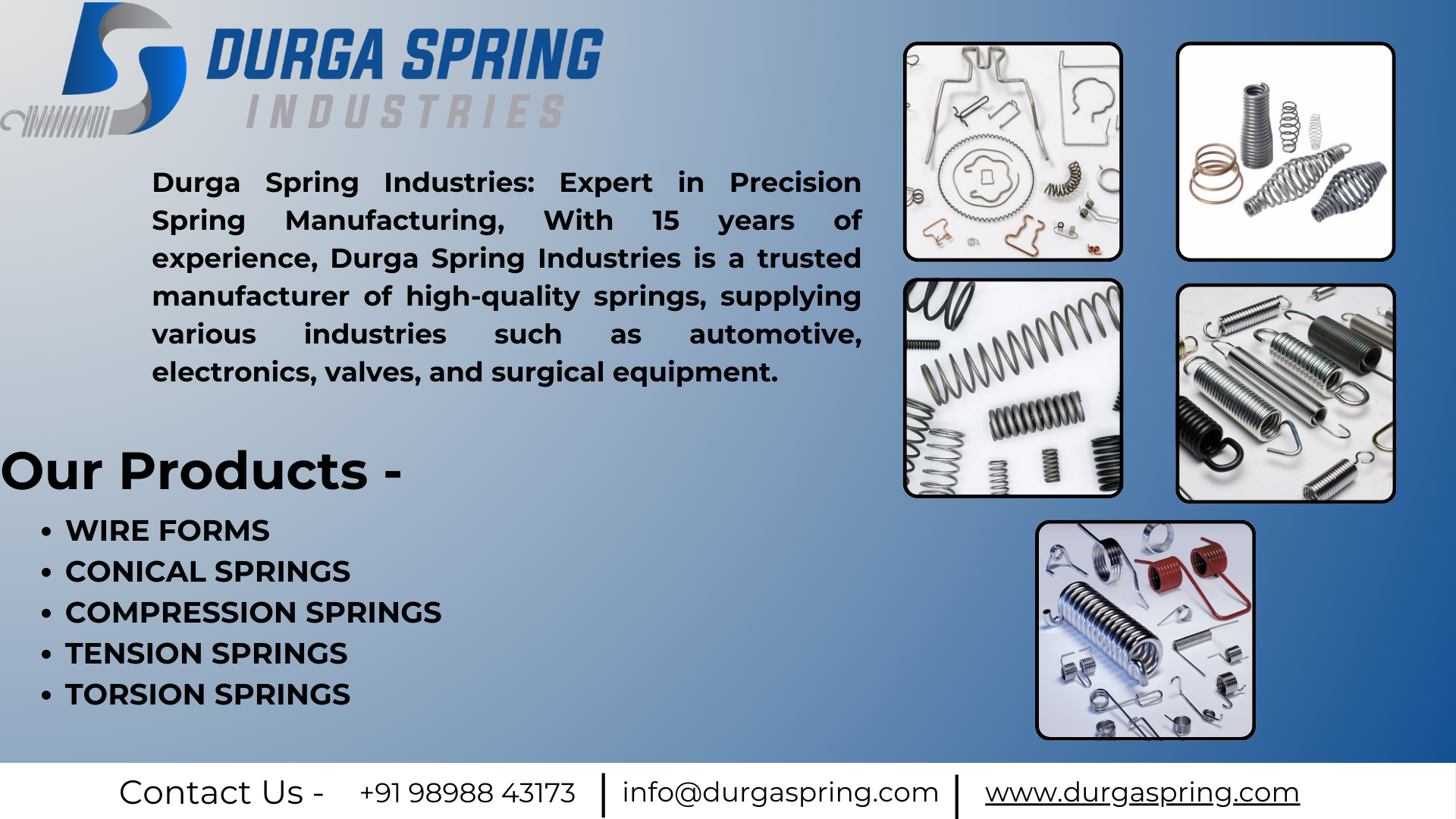

Durga Spring is recognized as a premier Wire Form Solutions Supplier in Gujarat, serving as a critical partner for industries seeking reliable, high-quality, and diverse industrial wire component provider Gujarat. Our extensive capability spans from manufacturing simple, high-volume custom wire clips supplier Ahmedabad needs to complex, precision wire linkages. Leveraging state-of-the-art CNC wire bending solutions Gujarat**-based operations, we provide comprehensive, end-to-end solutions that cover design consultation, material selection, production, and finishing, ensuring total customer satisfaction across the state.

Our commitment to being a full-service wire form solution provider means we offer unparalleled flexibility in manufacturing:

As a leading wire form solutions supplier in Gujarat, Durga Spring is not merely a manufacturer but a strategic extension of your production line. We understand the competitive pressure in the industrial landscape of Gujarat and strive to deliver components that enhance both performance and cost-efficiency. Partner with us for reliable supply, technical excellence, and a broad product portfolio that meets your every requirement for **comprehensive wire forms Gujarat**. Let us solve your most challenging wire component needs.

Durga Spring• We’re here to help

Filter Using Product Tags