Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

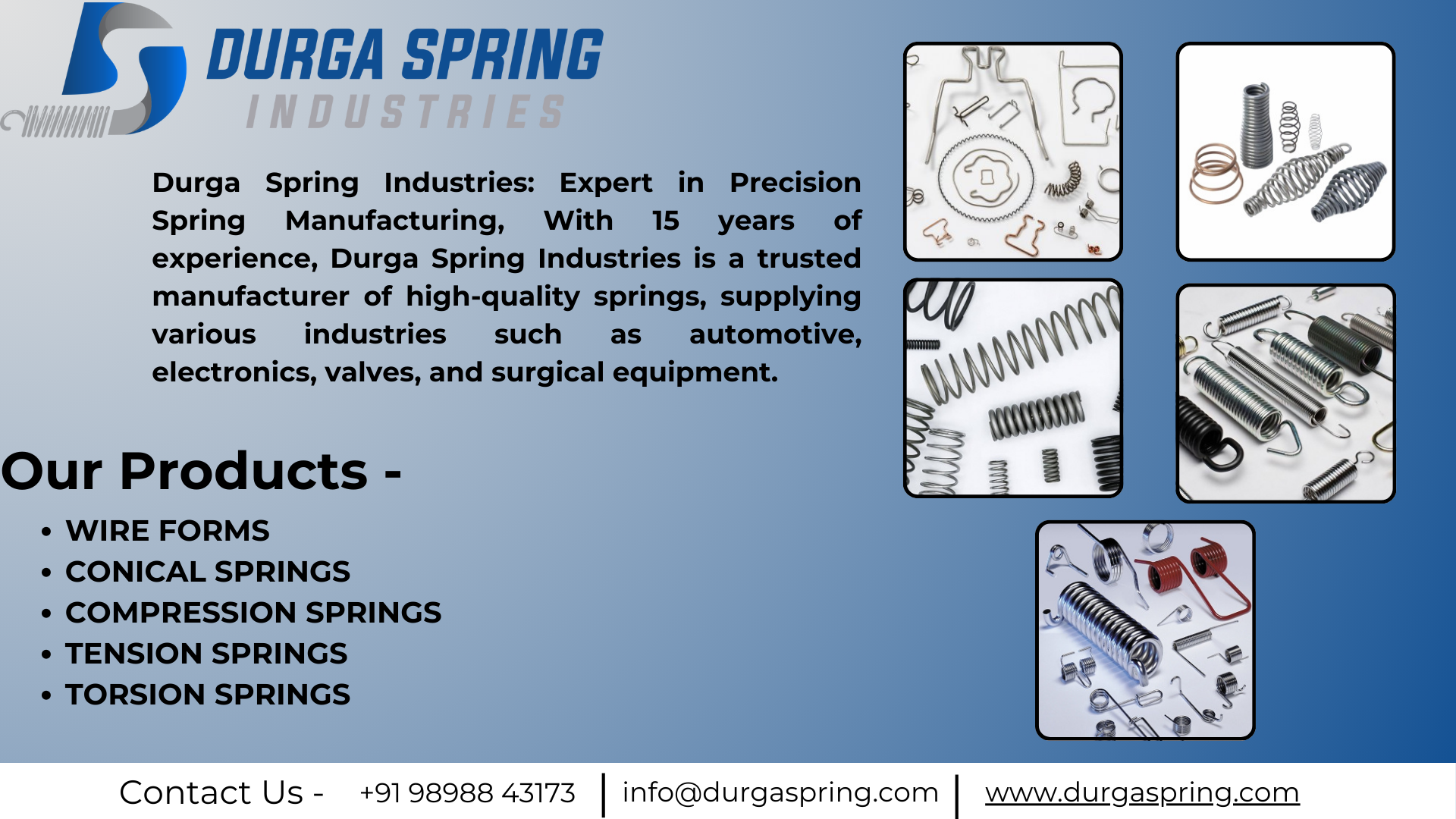

Compression Spring Manufacturers in Ahmedabad

Compression spring manufacturers in Ahmedabad are known for delivering precision-engineered, high-strength helical springs used across industrial and commercial sectors. Ahmedabad, being a major engineering and manufacturing hub in India, houses some of the top-rated spring manufacturers that offer custom and standard compression springs in various materials, dimensions, and load capacities for local and global clients.

These manufacturers supply springs that meet ISO, IS, and DIN standards, and are recognized for quality consistency, material integrity, and affordable bulk production.

Material Preparation

Springs are made using high-tensile spring steel, stainless steel (SS304, SS316), music wire, or alloy steels

Coiling Process

The wire is cold-formed using automated CNC spring coiling machines, ensuring precision pitch and coil count

For larger springs, hot coiling is used

Heat Treatment

Grinding (If Required)

Spring ends are ground flat to improve stability and load transfer in heavy applications

Surface Treatment

Options include black oxide, zinc coating, powder coating, or shot peening for corrosion resistance

Quality Testing

Load deflection tests, dimensional checks, fatigue testing, and spring rate validation are conducted before delivery

Automotive & railways – shock absorbers, clutch assemblies

Textile machinery – tension control units

Pumps and valves – for actuation and sealing

Agricultural equipment – planters, tillers, and sprayers

Medical devices – diagnostics and spring-loaded tools

Industrial machines – presses, jigs, fixtures

Consumer goods – pen mechanisms, push buttons, toys

Spring shapes: Cylindrical, conical, barrel-shaped

Load types: Linear, progressive, or variable pitch

Surface finishes: Electroplated, black oxide, or custom

Corrosion-resistant for harsh or outdoor conditions

Available as per IS 7906 / DIN 2095 / ASTM standards

Maintain force balance and return motion in dynamic assemblies

Critical for shock absorption, force storage, and component positioning

Allow for compact design solutions in space-constrained equipment

Play a vital role in safety systems, automation, and control mechanisms

Durable and fatigue-resistant even under repetitive stress

Easy to customize as per client specifications

Low cost per unit in bulk quantities

Compact size, reliable functionality

Supported by fast delivery and local manufacturing in Ahmedabad

Ahmedabad has a rich industrial base with decades of spring manufacturing expertise

Equipped with modern CNC, testing, and heat-treatment infrastructure

Quick turnaround time and affordable pricing

Suppliers offer OEM customization, engineering consultation, and CAD support

Strict adherence to quality standards and client specifications

Strong logistics network ensures pan-India and international shipping

Compression spring manufacturers in Ahmedabad combine precision engineering, cost-effective production, and custom flexibility to serve both standard and specialized spring needs. Whether you’re an OEM, exporter, equipment builder, or repair company, Ahmedabad-based suppliers offer reliable, tested, and high-performance spring solutions with excellent after-sales and technical support.

Website:-https://durgaspring.com/

Filter Using Product Tags