Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

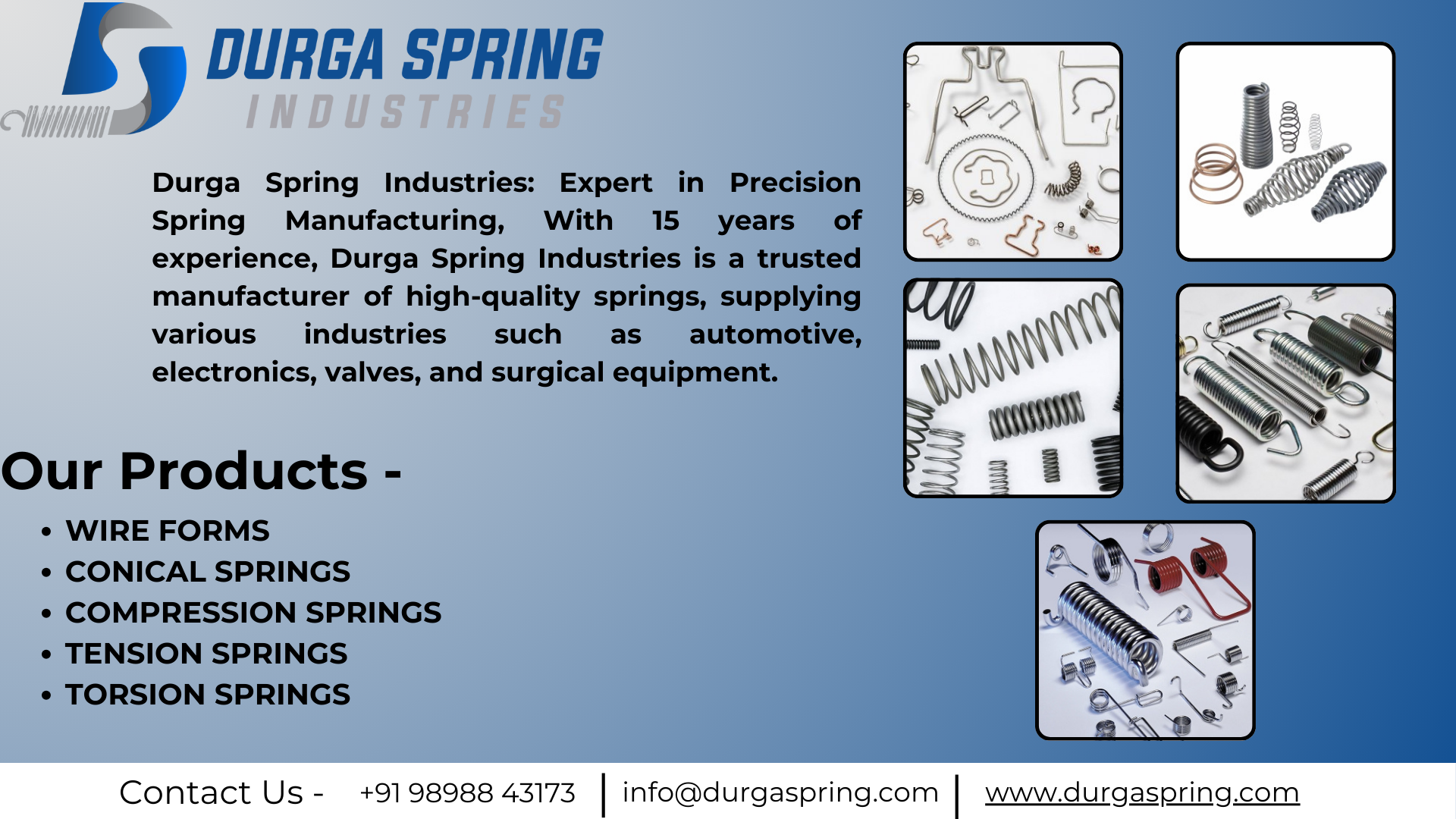

As a leading High-Performance Spiral Spring Supplier Gujarat, Durga Spring is dedicated to manufacturing precision flat springs, often referred to as power springs, engineered for the most critical applications in industrial, automotive, and specialized sectors. Our springs are designed to deliver high energy density and exceptional **consistent torque** over a predictable, long **cycle life**, exceeding standard commercial requirements. Located strategically in Ahmedabad, we cater to the high-tech and fast-growing industries throughout Gujarat and across India.

True high-performance spiral springs require superior quality control at every stage. Durga Spring achieves this through:

As a key **High-Performance Spiral Spring Supplier Gujarat**, Durga Spring serves as a strategic partner to manufacturers demanding the highest levels of component reliability. We understand the competitive pressure and technical complexity of industries operating in Western India. Our commitment is to deliver precision-engineered power springs that integrate seamlessly into your most sophisticated products, ensuring performance and safety. Contact us for technical consultation and to discuss your requirements for **critical application power springs**.

Durga Spring• We’re here to help

Filter Using Product Tags