Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

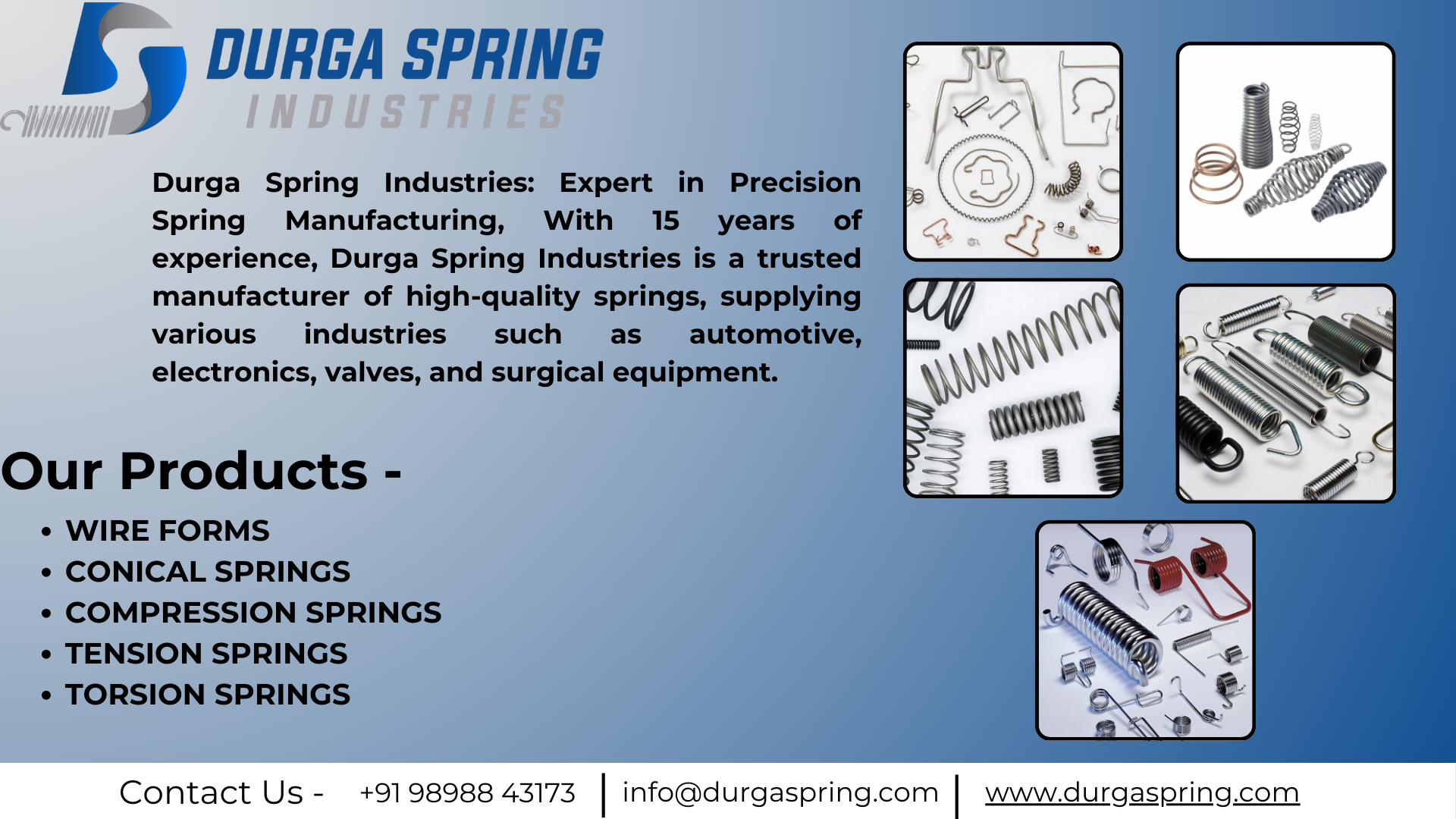

Tension

Springs Supplier in Gujarat

A Tension Spring (or Extension Spring) is a

vital mechanical component designed to store energy when it is stretched. These

springs are wound to provide force resistance when pulled apart, and they

return to their original shape when the force is released. Tension springs are

widely used across various industries, including automotive, machinery,

construction, and consumer goods.

As a prominent Tension Springs Supplier in Gujarat,

we provide customized, high-quality tension springs manufactured from premium

stainless steel, carbon steel, and alloy materials. Our products are

precision-engineered to meet diverse customer requirements for load

capacity, wire diameter, coil diameter, and length, ensuring long-lasting

performance and reliability.

Applications

of Tension Springs

Features

and Their Uses

|

Feature |

Use / Benefit |

|

High-Quality Stainless & Carbon Steel |

Superior corrosion resistance and long life in demanding environments |

Customizable Hook Types |

Suitable for different industrial and mechanical

applications |

|

Precision Wound Coils |

Ensures uniform force distribution over extended stretches |

|

Fatigue-Resistant Construction |

Ideal for applications requiring repeated cycling without

failure |

|

Wide Range of Wire Diameters |

From 0.2 mm to 20 mm, catering to light and

heavy-duty applications |

|

Durable Coatings (Zinc, Black Oxide) |

Protects against wear and corrosion, especially in humid

or corrosive environments |

|

High Load-Bearing Capacity |

Supports large forces, making it suitable for industrial

machinery and automotive applications |

|

Compact Design |

Space-saving design without compromising on strength and

performance |

|

ISO Certified Manufacturing |

Guarantees consistent quality with full traceability of

materials and production processes |

|

Long-Lasting Performance |

Provides reliability even under high-stress and high-load

conditions |

Top 10

FAQs About Tension Springs Supplier in Gujarat

Key

Selling Points for Tension Springs Supplier in Gujarat

Contact

Us For More Details On :

Call - +91 98988 43173

Email - info@durgaspring.com

Website –

www. durgaspring.com

YouTube -

www.youtube.com/@durgasprings

Facebook

- www.facebook.com/people/Durga-spring-industries

Filter Using Product Tags