Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

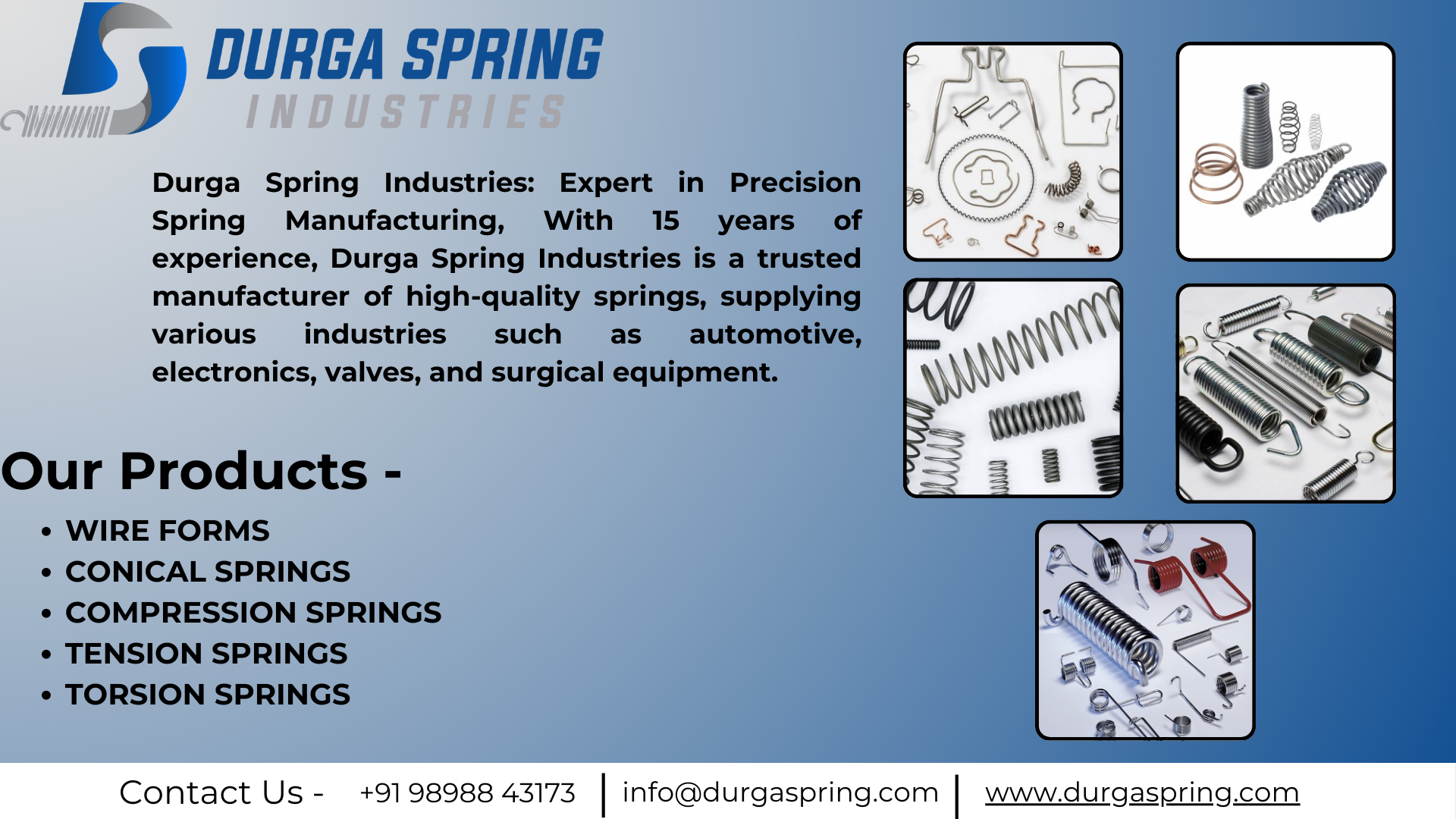

For global supply chains relying on precision components, partnering with a reliable Tapered Coil Spring Exporter in India is essential. Durga Spring excels as a global spring supplier, offering conical coil springs that meet stringent international quality standards. Tapered springs, also known as conical springs, are widely used for their ability to provide a high force and reduce solid height, making them ideal for automotive, power transmission, and aerospace industries. Our status as a leading Helical Tapered Spring Exporter is built on robust quality control, efficient logistics, and certified production methods, ensuring a seamless supply of custom tapered springs to clients worldwide.

Our success as a Spring Exporter India relies on manufacturing conical coil springs that perform reliably in any global application. We meet export requirements by focusing on:

Choosing Durga Spring, a specialized Tapered Coil Spring Exporter in India, ensures your international operations receive components of uncompromising quality delivered reliably. Our focus is on supporting OEMs and distributors globally by providing precision engineering and consistent manufacturing. We invite you to leverage our export expertise and competitive advantage. Contact our dedicated sales team today to discuss your large-volume requirements for conical springs and secure a dependable, long-term supply partner from India.

Durga Spring• We’re here to help

Filter Using Product Tags