Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

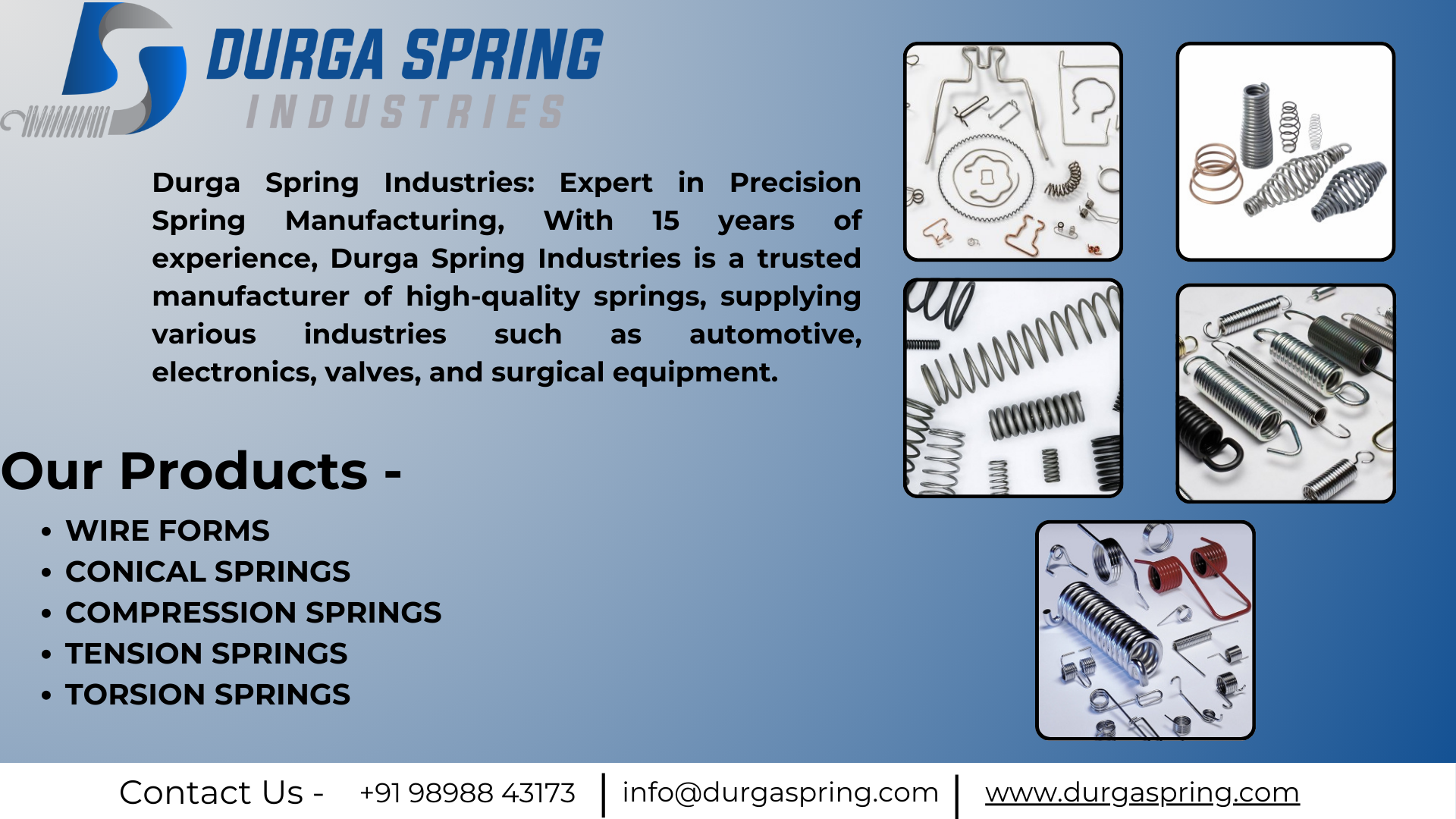

In the realm of high-load mechanical assemblies, the reliability of fastening components is non-negotiable. Durga Spring stands as a premier precision disc & spring washer manufacturer, dedicated to producing high-performance conical spring washers that provide consistent tension and shock absorption. Our disc springs are engineered to handle extreme loads in limited spaces, making them indispensable for industrial valves, clutch mechanisms, and heavy machinery. By utilizing advanced heat treatment processes and high-grade spring steel, we ensure that every washer maintains its elastic properties even under severe cyclical loading conditions.

As a specialized precision disc & spring washer manufacturer, we understand the nuances of spring rate, fatigue life, and deflection. Our production process involves:

Partnering with an experienced precision disc & spring washer manufacturer like Durga Spring ensures that your assemblies remain secure under the most demanding conditions. We don't just supply parts; we provide engineering support to help you select the correct washer stack for your application. Whether you need heavy-duty spring washers for infrastructure projects or precision conical washers for aerospace components, our team is equipped to deliver. Contact us today to discuss your technical specifications and experience the difference that precision manufacturing brings to your supply chain.

Durga Spring• Engineering Reliability

Filter Using Product Tags