Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

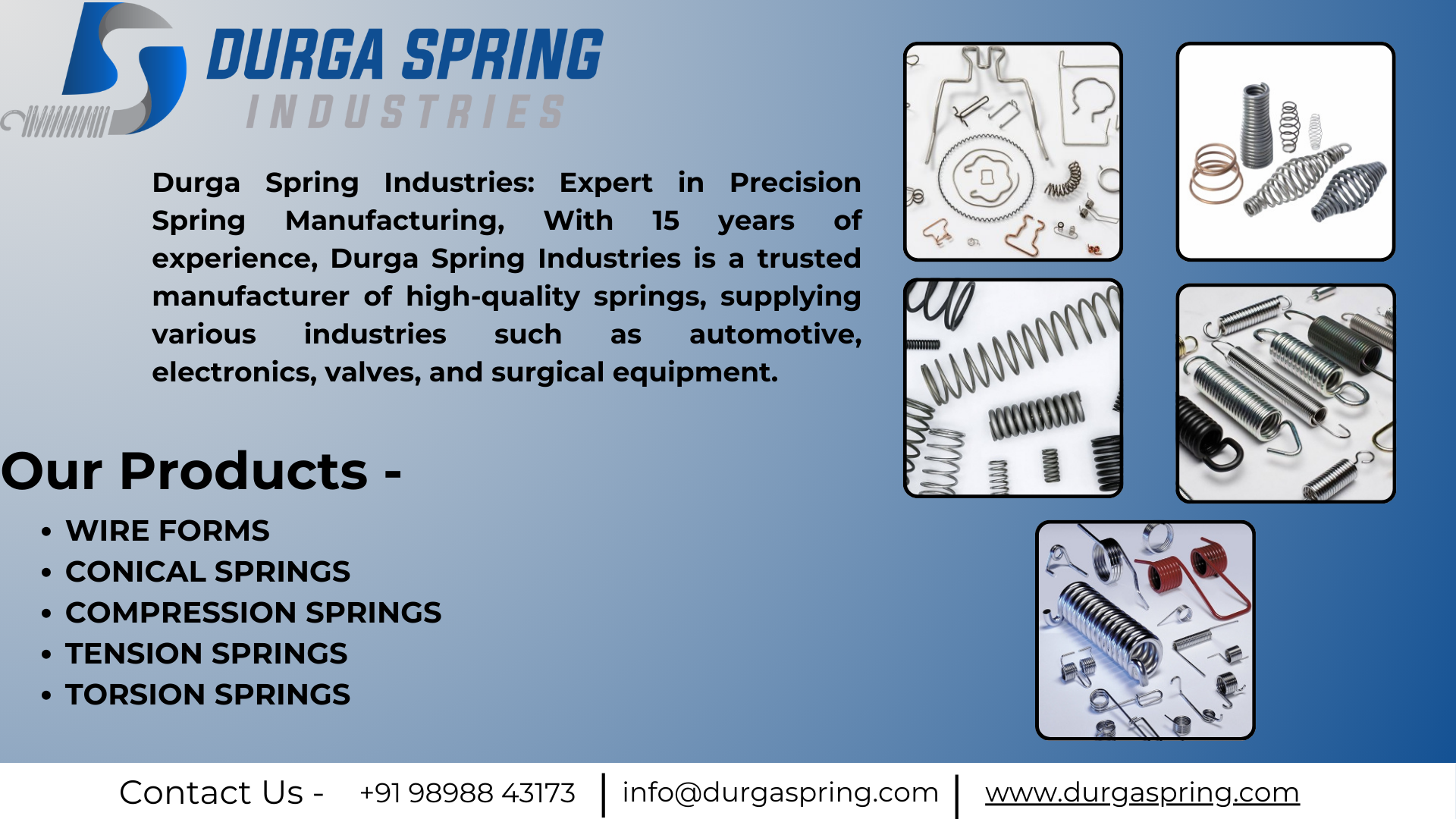

For businesses and traders seeking to **buy spring washers in Ahmedabad**, Durga Spring offers a reliable and centralized source for all helical lock washer requirements. We maintain a substantial inventory of standard and customized split washers, ensuring immediate availability for urgent production needs across the city’s vast industrial landscape. Our focus is on providing high-quality, corrosion-resistant, and dimensionally accurate washers suitable for critical applications in engineering, auto ancillary, and manufacturing sectors. Choose us as your trusted **Industrial Lock Washer Supplier Ahmedabad** for quality you can depend on.

Sourcing fasteners locally provides significant advantages, especially when speed and precision are paramount. We streamline the process to help you **buy spring washers in Ahmedabad** efficiently:

If your project demands immediate and consistent supply, choosing a local **Fastener Stockist Ahmedabad** like Durga Spring is the most strategic decision. We simplify the procurement process, offering superior quality spring washers backed by manufacturing expertise. Whether you require a single box of standard MS washers or several tonnes of specialized stainless steel lock washers, we encourage you to visit our facility or contact our sales desk to discuss how we can meet your specific demands efficiently and reliably in Ahmedabad.

Durga Spring• We’re here to help

Filter Using Product Tags