Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Tripotassium EDTA Manufacturer in Ahmedabad, Gujarat

Tripotassium EDTA (C??H??K?N?O?) is a specialized chelating agent used to bind and neutralize metal ions such as calcium, magnesium, iron, and copper. It is extensively applied across industries like cosmetics, agriculture, pharmaceuticals, water treatment, and cleaning solutions. As a chemical manufacturing hub, Ahmedabad in Gujarat is home to several trusted and efficient manufacturers of Tripotassium EDTA, known for producing high-purity, stable, and export-grade quality.

These manufacturers use technologically advanced processes to ensure consistency, safety, and performance of the chemical for various formulations.

The production process in Ahmedabad follows a strict quality-controlled method:

High-grade EDTA acid and potassium hydroxide (KOH) are sourced and prepared.

EDTA is mixed with KOH in a jacketed stainless steel reactor, maintaining optimum pH and temperature.

This reaction forms Tripotassium salt of EDTA, ensuring precise chelation strength.

The reaction mixture is passed through industrial filters to eliminate impurities and unreacted particles.

The filtered solution is either spray dried to form powder or cooled for crystallization.

Every batch is tested for purity, pH, solubility, metal content, and chelation index.

The final product is packed in 25 kg HDPE bags, fiber drums, or custom export packaging.

Personal Care Products: Creams, shampoos, face washes

Agriculture: Micronutrient chelation for foliar sprays and fertilizers

Pharmaceuticals: Enhances formulation stability

Household & Industrial Cleaners: Improves performance in hard water

Paints and Dyes: Prevents discoloration caused by metal ions

Textiles & Paper: Used in dyeing and sizing to stabilize chemical baths

Appearance: White crystalline or powder

Solubility: Fully soluble in water

pH (1% solution): 10.5–12

Shelf Life: Up to 3 years in sealed packaging

Eco-Safe, Phosphate-Free

High thermal and pH stability

Neutralizes metal ions, ensuring chemical stability

Improves shelf life of formulations by preventing oxidation

Enhances bioavailability of nutrients in agricultural products

Offers a safer, non-phosphate alternative for eco-conscious industries

Prevents color fading and degradation in sensitive products

Essential additive in formulations involving metal ion-sensitive compounds

High-purity manufacturing with batch-wise testing

Offers excellent stability in alkaline formulations

Compatible with most cosmetic, pharma, and agri ingredients

Cost-effective and scalable supply options

Custom packaging and technical support provided

Backed by ISO-certified production facilities

Ahmedabad is part of India’s top chemical cluster, with world-class infrastructure

Easy access to logistics hubs and ports (Mundra, Kandla)

Home to well-established chemical companies with export credibility

Manufacturers offer customization, private labeling, and OEM services

Strong quality assurance, certifications (ISO, GMP, REACH), and documentation

Highly experienced in international trade, regulatory compliance, and bulk supply

Ahmedabad-based manufacturers of Tripotassium EDTA offer the perfect balance of quality, technical support, cost-efficiency, and reliability. Backed by Gujarat’s robust chemical industry, these suppliers serve industries across India and overseas with high-performance products, prompt logistics, and regulatory compliance. Whether you’re in cosmetics, agriculture, or chemical formulation, sourcing from Ahmedabad ensures your formulations remain stable, safe, and effective.

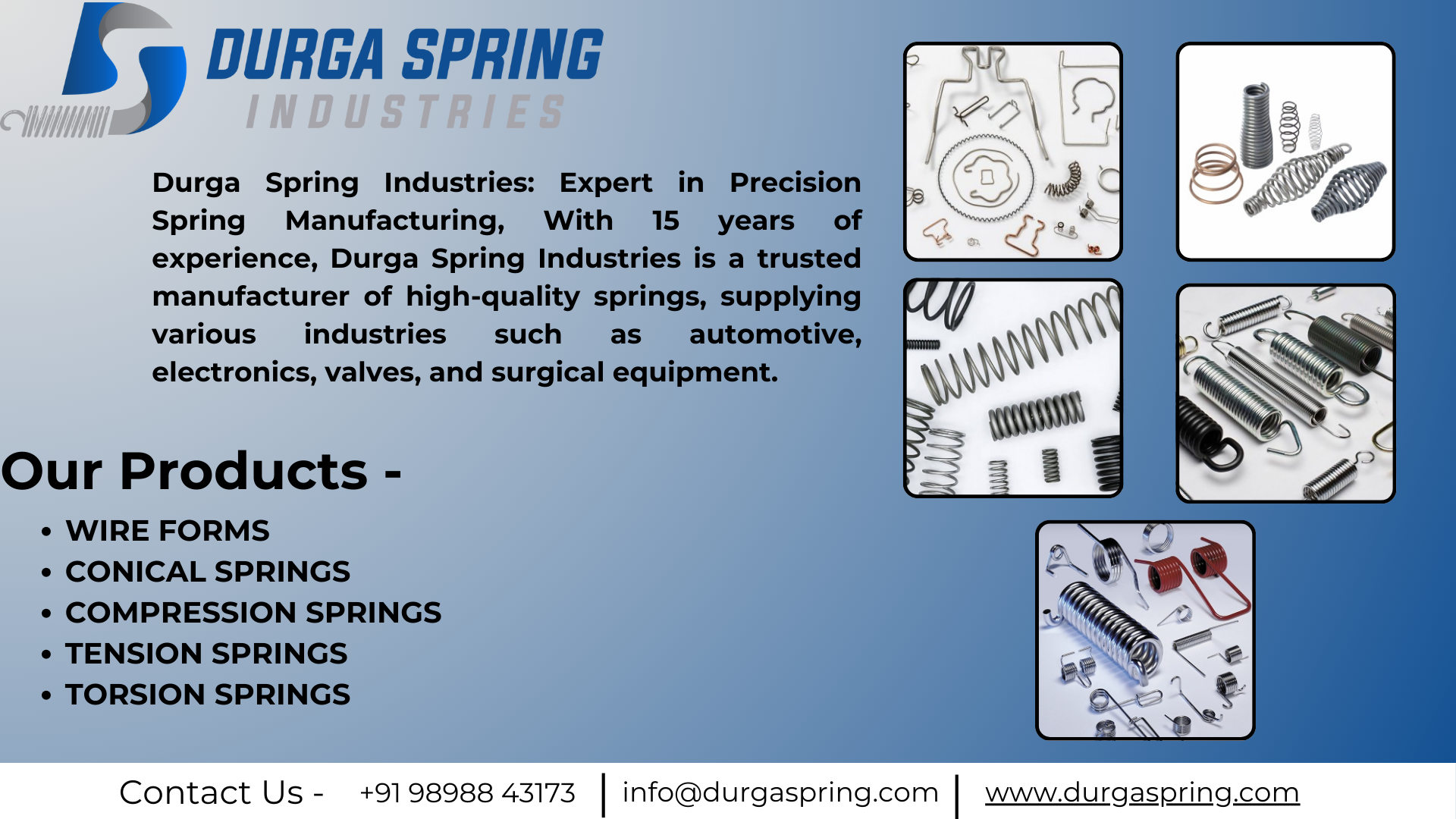

Gmail:-info@durgaspring.com

Website:-https://durgaspring.com/

Filter Using Product Tags