Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

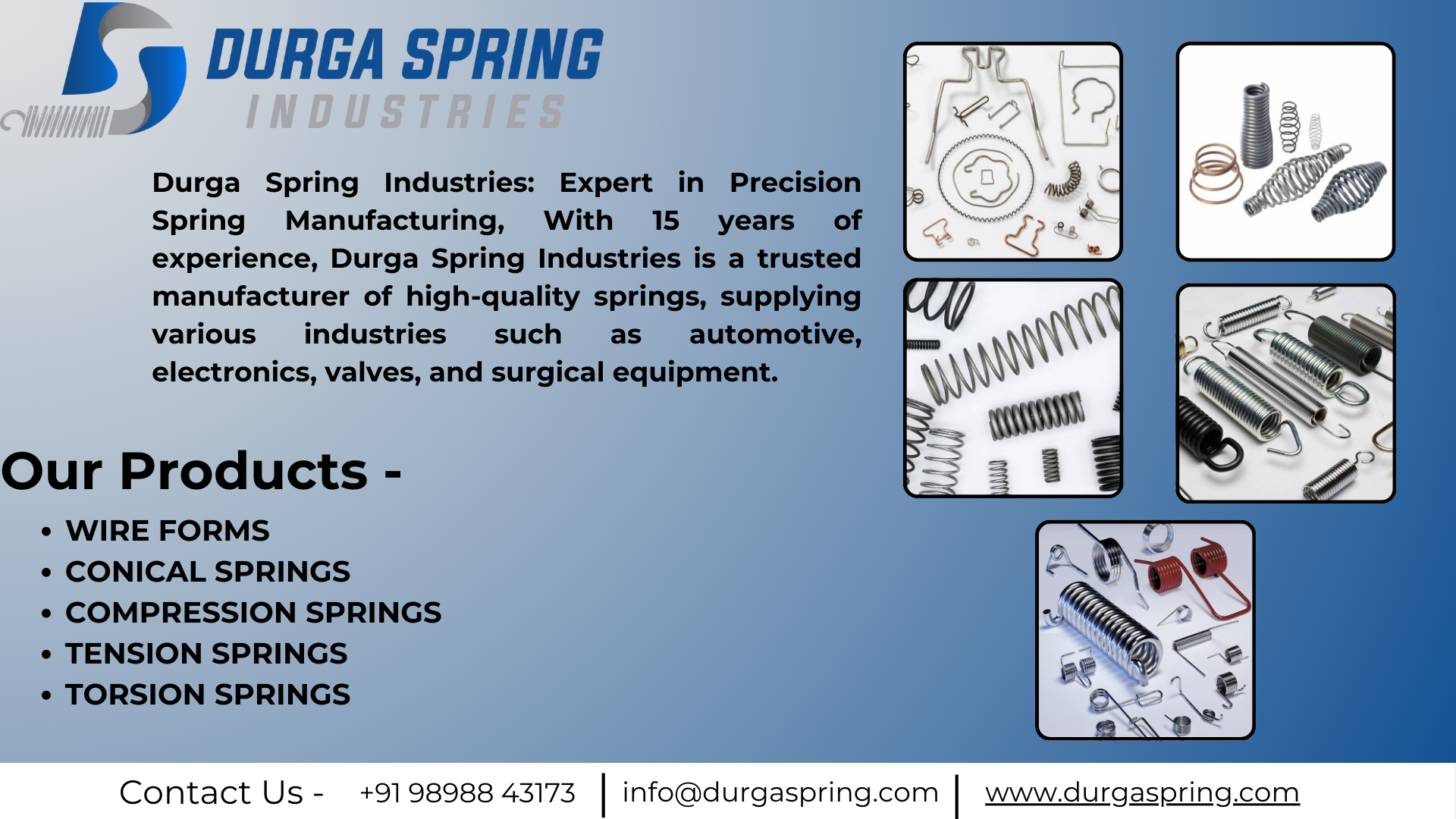

Durga Spring stands as a trusted **Precision Conical Spring Supplier in Gujarat**, dedicated to delivering custom-engineered springs that meet the most rigorous tolerance demands of modern industry. Conical springs, also known as tapered compression springs, are vital for applications requiring a progressive force increase and minimal solid height. Our expertise in advanced **CNC Coiling Gujarat** ensures geometric accuracy, load linearity, and superior fatigue life, making us the preferred supplier for high-stakes sectors like heavy machinery, electronics, and precision instrumentation throughout the state.

Precision is paramount when dealing with the progressive rate and nesting requirements of **conical springs**. We achieve superior quality through:

If your application demands **high tolerance conical springs** or requires a customized **progressive rate spring** solution, Durga Spring is your ideal partner in Gujarat. We combine decades of spring manufacturing experience with modern technology to consistently meet and exceed expectations for complexity and performance. We welcome engineers and procurement managers from the industrial corridor of Gujarat to consult with our technical team to receive tailored spring solutions that drive performance and reliability in your final products.

Durga Spring• We’re here to help

Filter Using Product Tags