Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

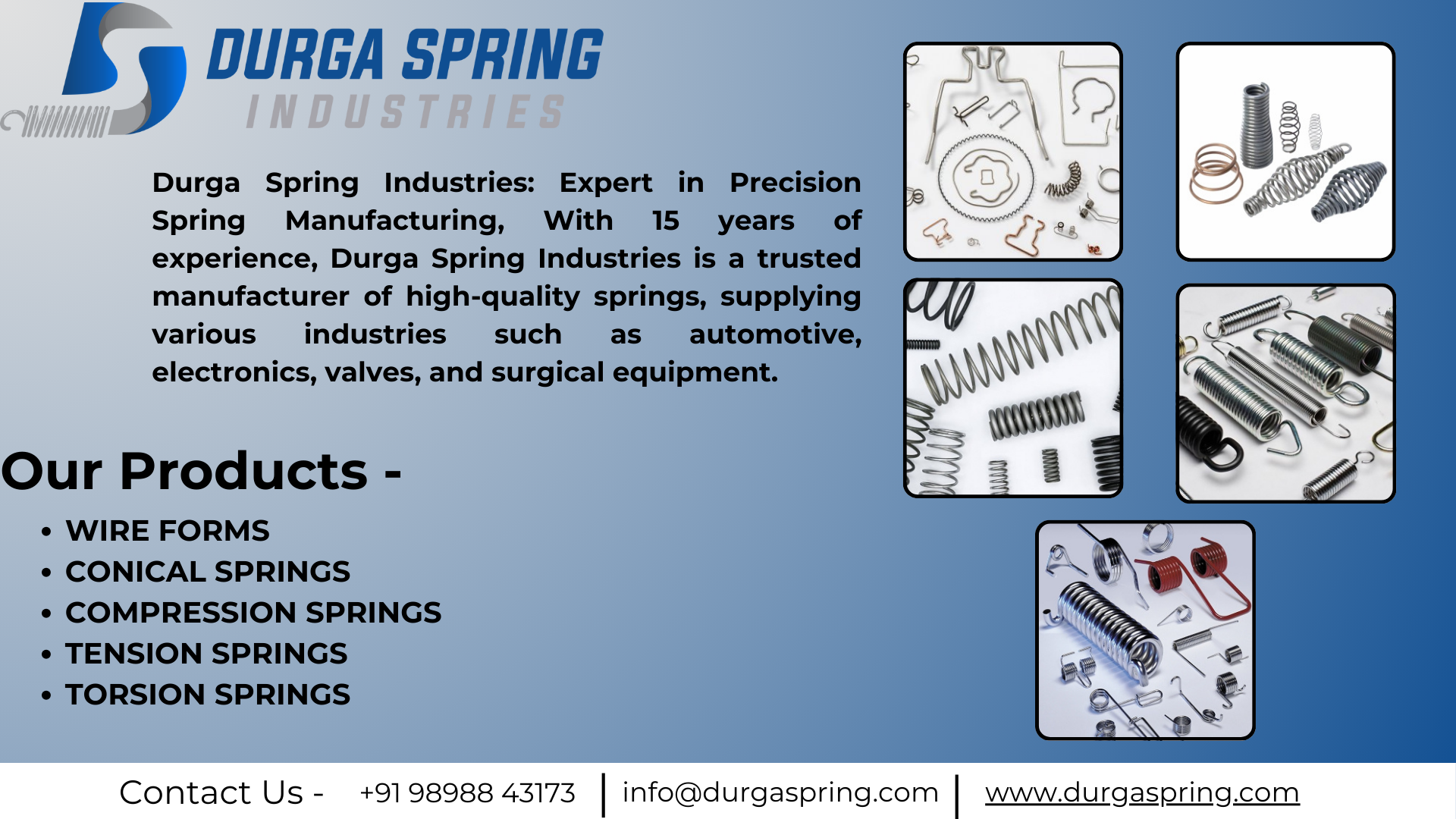

In a vast industrial landscape, selecting from the many trusted wire form manufacturers in India is paramount for ensuring product quality and supply chain stability. Trust is earned through consistent performance, unwavering quality, and transparent practices. Durga Spring Industries has established itself as a trusted name by delivering precision-engineered wire forms to diverse sectors across the nation. Wire forms are not mere components; they are critical elements in automotive systems, electrical circuits, and industrial machinery. Partnering with a trusted manufacturer like Durga Spring guarantees that every clip, spring, and linkage is crafted to perfection, supporting the integrity and performance of your final product.

Trusted wire form manufacturers in India build their reputation on a foundation of robust and repeatable manufacturing processes. At Durga Spring, this begins with the meticulous selection of high-quality raw materials sourced from certified suppliers. Our production facility is powered by advanced CNC wire bending technology, enabling us to produce complex components with exceptional accuracy and consistency across high-volume orders. Every stage of production is governed by stringent quality control protocols. From initial wire straightening to final finishing treatments like plating or coating, we ensure that each part meets our high standards and the specific requirements of our clients, solidifying our position as a reliable partner.

When evaluating trusted wire form manufacturers in India, it is essential to look beyond the factory floor. A truly reliable partner offers a seamless experience, from initial consultation and design support to prototyping and final delivery. Durga Spring Industries is committed to building lasting relationships with our clients, founded on open communication and a deep understanding of their needs. Our nationwide logistics network ensures that no matter where your facility is located in India, you receive high-quality wire forms on schedule. Choose a partner whose reputation for reliability is as strong as the components they produce.

Durga Spring• We’re here to help

Filter Using Product Tags