Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

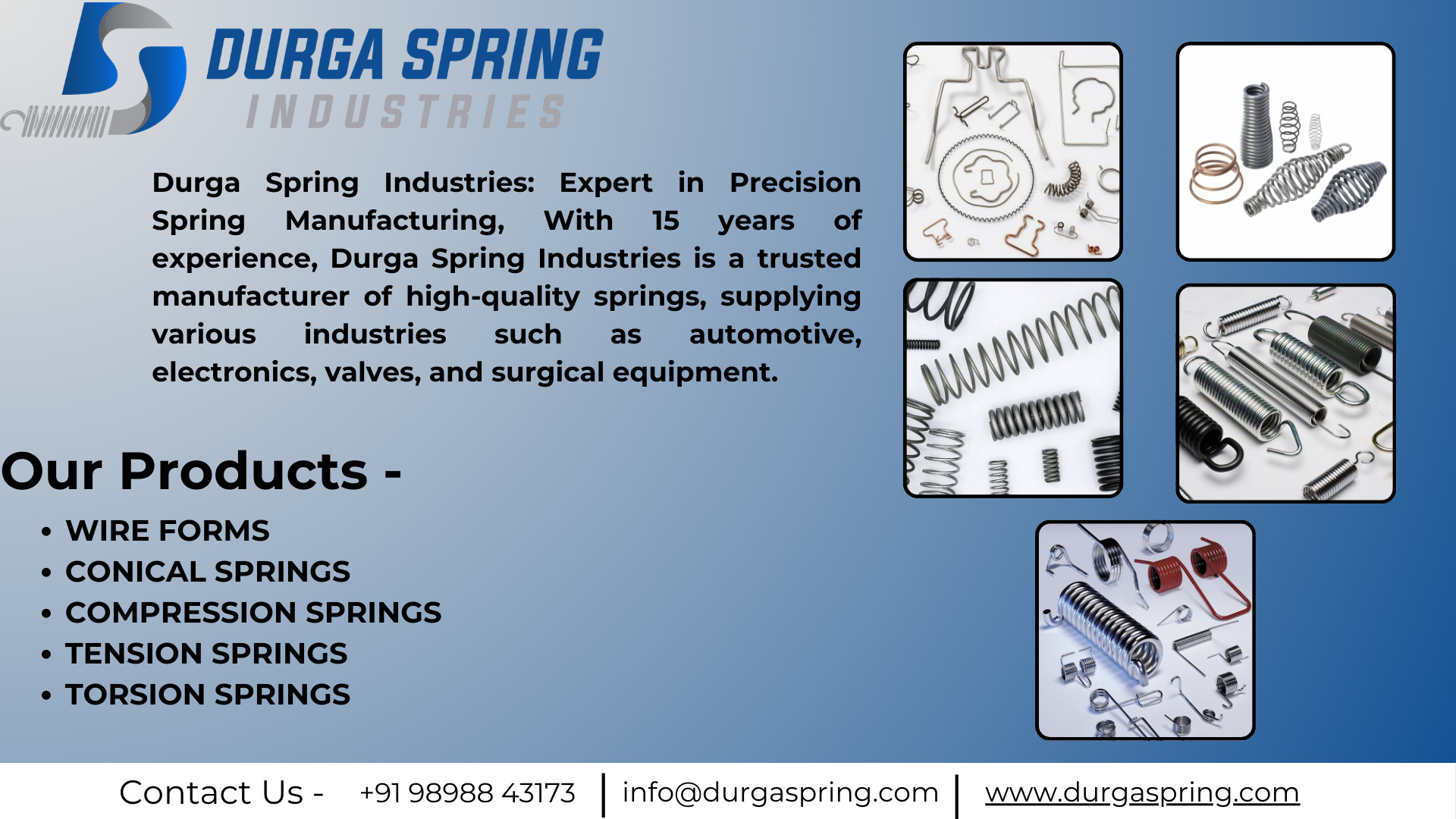

Not every engineering challenge can be solved with off-the-shelf components. Durga Spring has established itself as a reliable custom spring washers supplier in Gujarat, catering to the specialized needs of industries across Ahmedabad, Vadodara, and Surat. We understand that unique machinery requires washers with specific dimensions, load ratings, and material compositions. Whether you need a non-standard diameter, a specific gap width, or washers made from exotic alloys, our flexible manufacturing setup allows us to produce bespoke locking components that integrate perfectly into your custom assemblies.

Our expertise lies in bridging the gap between design concepts and tangible products. As a specialized supplier, we offer comprehensive customization options:

Working with a dedicated custom spring washers supplier in Gujarat gives you the advantage of agility and technical collaboration. Durga Spring focuses on building long-term relationships with engineering firms and OEMs who require more than just a standard hardware supplier. We invite design engineers and purchase heads to share their technical drawings or samples. Our team will evaluate the feasibility and provide a tailored manufacturing proposal, ensuring that your specialized equipment gets the precise fastening support it deserves.

Durga Spring• We’re here to help

Filter Using Product Tags