Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

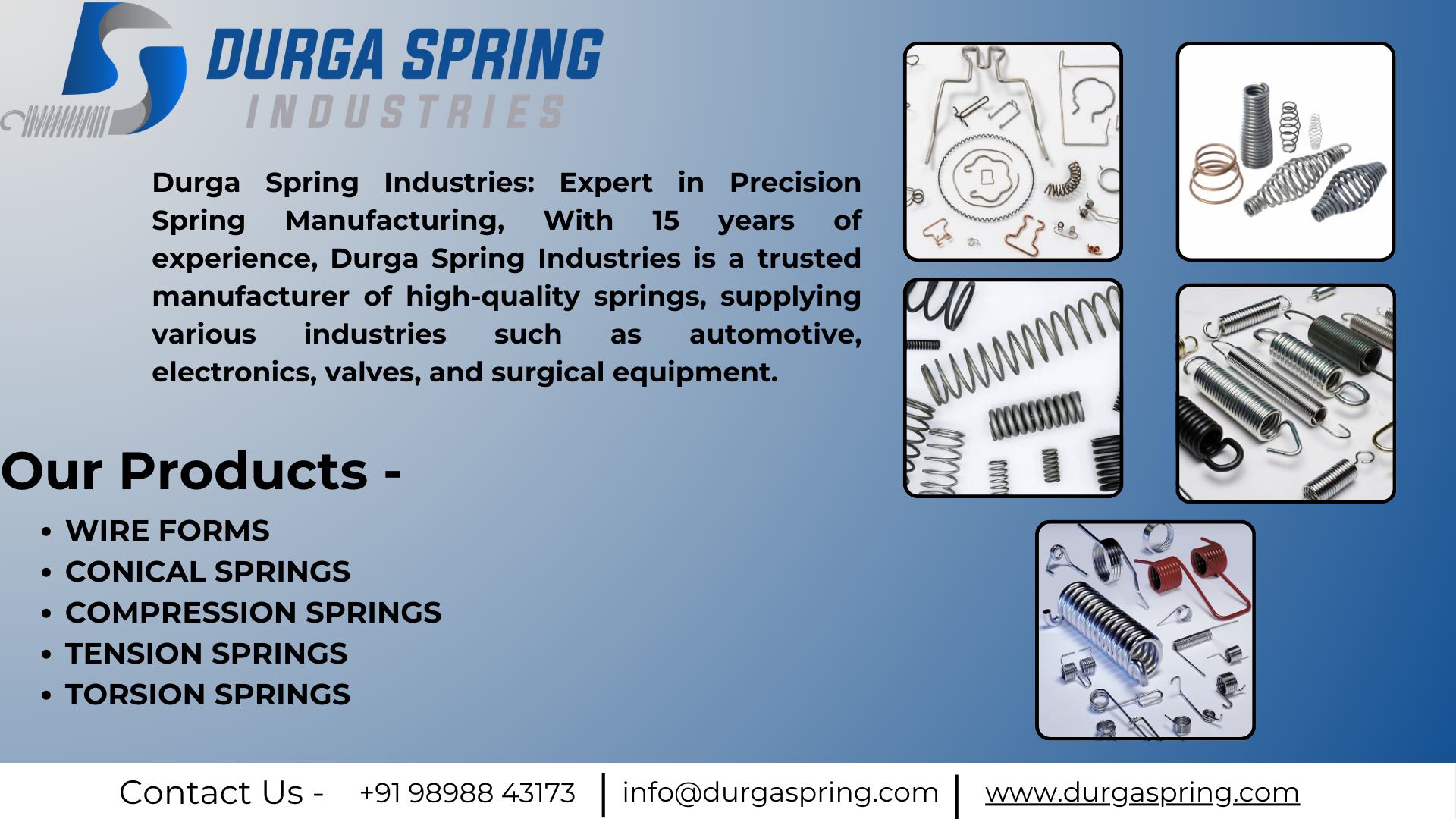

Compression Spring Supplier in Ahmedabad

Compression springs are helical mechanical components designed to resist compressive forces and store energy when compressed. These springs are typically open-coil and cylindrical in shape, though conical and barrel forms are also used for special applications.

Suppliers and manufacturers in Ahmedabad produce custom and standard compression springs using high-tensile wire grades and precision coiling technologies, catering to industries such as automotive, electronics, engineering machinery, valves, and appliances.

Material Selection:

Made from high-carbon steel, stainless steel (SS 302, 304, 316), music wire, phosphor bronze, or alloy steel based on load requirements and environment.

Wire Coiling:

The wire is coiled into a helical shape using CNC spring coiling machines, with control over pitch, coil diameter, and number of turns.

Heat Treatment:

Springs are heat-treated to relieve internal stress and improve elasticity and fatigue life.

Grinding (Optional):

End faces are ground flat to improve load-bearing surface and stability when compressed.

Surface Finishing:

Surface treatment such as shot peening, electroplating, powder coating, or black oxide is applied to prevent corrosion.

Load Testing:

Final springs undergo load deflection and fatigue testing using computerized spring testers to ensure they meet design tolerances.

Automobile Suspension & Clutches

Electronic Connectors, Switches, and Relays

Industrial Machines and Tools

Valves, Pumps, and Actuators

Medical Devices and Laboratory Equipment

Aerospace, Defense, and Railways

Wire Diameter Range: 0.2 mm to 20 mm

Material Grades: SS 302/304/316, EN 47, Inconel, Phosphor Bronze

Coil Configurations: Cylindrical, Conical, Barrel

Precision Grade: Class I to Class III (IS/ASTM specs)

Load Capacity: From a few grams to hundreds of kg

Temperature Range: Up to 250°C for standard steels; more for exotic alloys

Compression springs play a critical role in absorbing shock, returning energy, and maintaining contact force in moving systems. They are essential components in precision mechanical designs, ensuring both performance and safety in machines and devices.

High Energy Storage in Compact Size

Durable Under Repeated Compression Cycles

Customizable Shape, Pitch, and Strength

Versatile Applications Across Sectors

Cost-Effective with Long Service Life

In high-performance assemblies, from aircraft seats to engine valves, compression springs ensure constant pressure, secure contacts, and vibration damping. As a result, they are among the most widely used and engineered spring types worldwide.

Size/Grade |

Quantity |

Approx Price (INR/Piece) |

|---|---|---|

| Micro Springs (0.5–1 mm dia) | ?1.20 – ?3.00 | |

| Medium Load Springs (2–6 mm dia) | 500+ pcs | ?4 – ?12 |

| Heavy-Duty Springs (8–20 mm dia) | 100+ pcs | ?25 – ?100+ |

Q1. Can compression springs be customized by load and stroke?

A: Yes, suppliers in Ahmedabad offer custom-designed springs based on desired force, deflection, and application geometry.

Q2. Do you offer corrosion-resistant springs?

A: Absolutely. Stainless steel and plated finishes are available for moisture or chemical resistance.

Q3. What tolerances can you maintain?

A: Most manufacturers meet IS, DIN, or ASTM tolerances, typically within ±0.1 mm for critical dimensions.

Q4. Are prototypes or low volumes accepted?

A: Yes, many suppliers accept prototypes and development samples for new designs or OEM needs.

Q5. What is the lead time for bulk orders?

A: Usually 7–15 working days, depending on quantity and customization.

As a reliable Compression Spring Supplier in Ahmedabad, manufacturers provide precision, durability, and customization for a wide range of mechanical needs. With advanced CNC machines, testing labs, and material options, Gujarat’s spring suppliers ensure quality assurance, bulk capability, and customer-focused engineering.

Whether for automotive, aerospace, or industrial machines, compression springs remain indispensable components for motion, resilience, and energy control.

Website:-https://durgaspring.com/

Filter Using Product Tags