Torsion Spring Supplier in Gujarat

Torsion Spring Supplier in Gujarat

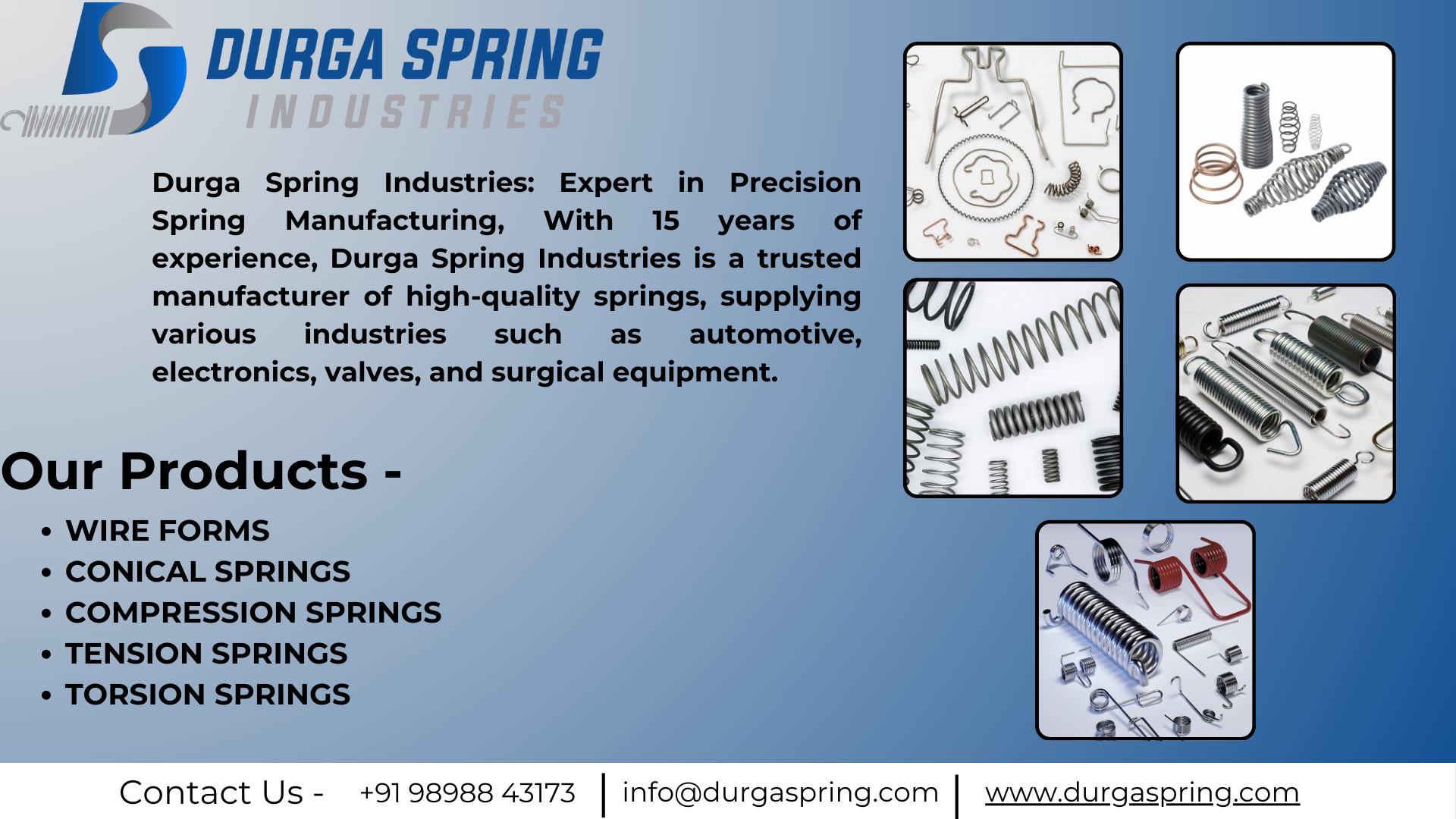

Description

Torsion springs are precision-engineered components used to exert rotational force. These springs are ideal for various mechanical assemblies where torque is required to rotate, hold, or return a component. As a reputed torsion spring supplier in Gujarat, DURGA SPRING provides high-performance torsion springs manufactured with quality materials, strict tolerances, and innovative designs to meet industry-specific applications.

Applications and Benefits

Applications:

• Rolling shutter systems

• Vehicle suspension and clutches

• Industrial machinery and tools

• Electrical devices and contact systems

• Garage doors and locksBenefits:

• Efficient torque control

• Compact spring mechanism

• Durable under repetitive use

• Excellent elasticity and memory

• Customizable leg angles and configurations

Key Features

• High tensile strength spring steel

• Right or left coil direction

• Choice of finishes: black oxide, zinc, or stainless

• Consistent torque delivery

• Fully customizable size and torque rating

Where It’s Used

• Automotive industry

• Aerospace components

• Construction tools

• Agricultural machines

Uses

• Returning components to original position

• Applying rotational force

• Locking or triggering mechanisms

• Maintaining component alignment

Importance and Significance

Torsion springs play a crucial role in devices that require movement control or energy storage in a rotational format. Being a leading torsion spring supplier in Gujarat, DURGA SPRING ensures all springs are crafted with high fatigue resistance, dimensional accuracy, and strength to withstand dynamic applications.

Why Choose Us

• Gujarat-based trusted supplier

• Timely delivery and bulk order handling

• Advanced coiling and forming technology

• Quality assurance and material certification

• Expertise in custom spring designs

Manufacturer & Supplier in India

DURGA SPRING is a trusted name among torsion spring suppliers in Gujarat. With a strong presence in India’s spring manufacturing industry, we supply torsion springs that are tested and validated for demanding applications. Our solutions serve multiple sectors with precision and reliability.

FAQs

What torque range do your torsion springs cover?

We manufacture torsion springs based on custom torque requirements from low to high range.Can I specify coil direction?

Yes, both left-hand and right-hand coiling options are available.Do you supply to other Indian states?

Yes, we supply across Gujarat and pan India.What is the delivery time?

Delivery usually takes 7–15 working days depending on order quantity and customization.Do you provide finishing options?

Yes, finishes like powder coating, galvanizing, and black oxide are available.Are samples available?

Yes, we provide samples for design validation and approval.What wire diameters do you offer?

We offer a wide range starting from 0.3 mm to over 8 mm based on your needs.Can torsion springs be reused?

In some low-stress applications, yes, but ideally they are designed for single-application reliability.Do you follow IS or DIN standards?

Yes, all springs comply with Indian and international specifications as required.How can I request a quote?

Visit our website or contact us via phone or email with your specifications.

Conclusion

For superior quality torsion springs that meet industrial and mechanical precision requirements, choose DURGA SPRING – your go-to torsion spring supplier in Gujarat. Our expertise ensures springs that perform flawlessly in rotational and torque-based applications.

Contact Information

Contact: +91 98988 43173

Email: info@durgaspring.com

Website: https://durgaspring.com/

Filter Using Product Tags