Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

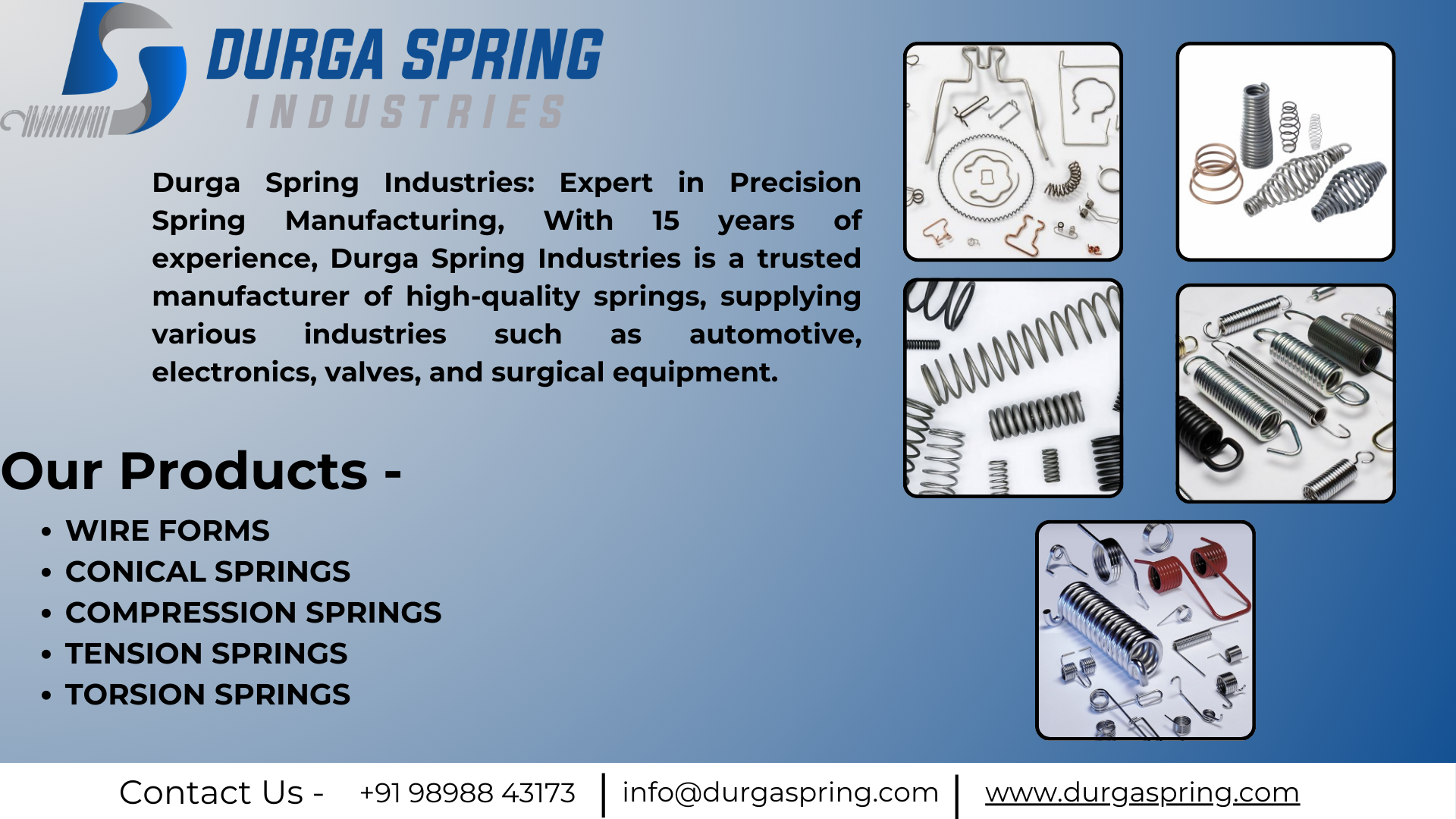

Durga Spring is recognized as a premier precision spiral spring manufacturer Ahmedabad for clients needing the highest levels of accuracy and reliability in flat, clock, and torsion springs. Located in the industrial heart of Gujarat, our facility is equipped with state-of-the-art machinery to manufacture high-accuracy flat spring supplier Gujarat products. We specialize in producing springs that offer consistent torque, predictable load characteristics, and exceptional cycle life, which are crucial for complex mechanical and electrical systems across India.

Manufacturing precision springs requires meticulous control over every process, from material preparation to final forming and finishing. As a dedicated clock spring manufacturer Ahmedabad, our process ensures:

If your application demands zero compromise on performance and longevity, choosing an experienced precision spiral spring manufacturer Ahmedabad is non-negotiable. Durga Spring combines geographical proximity in Gujarat with world-class manufacturing standards to deliver exceptional value. We welcome complex designs and prototype challenges for custom mechanical power springs India needs. Contact us today with your detailed blueprints, and let our engineering team translate your requirements into high-performance, precision spiral springs.

Durga Spring• We’re here to help

Filter Using Product Tags