Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

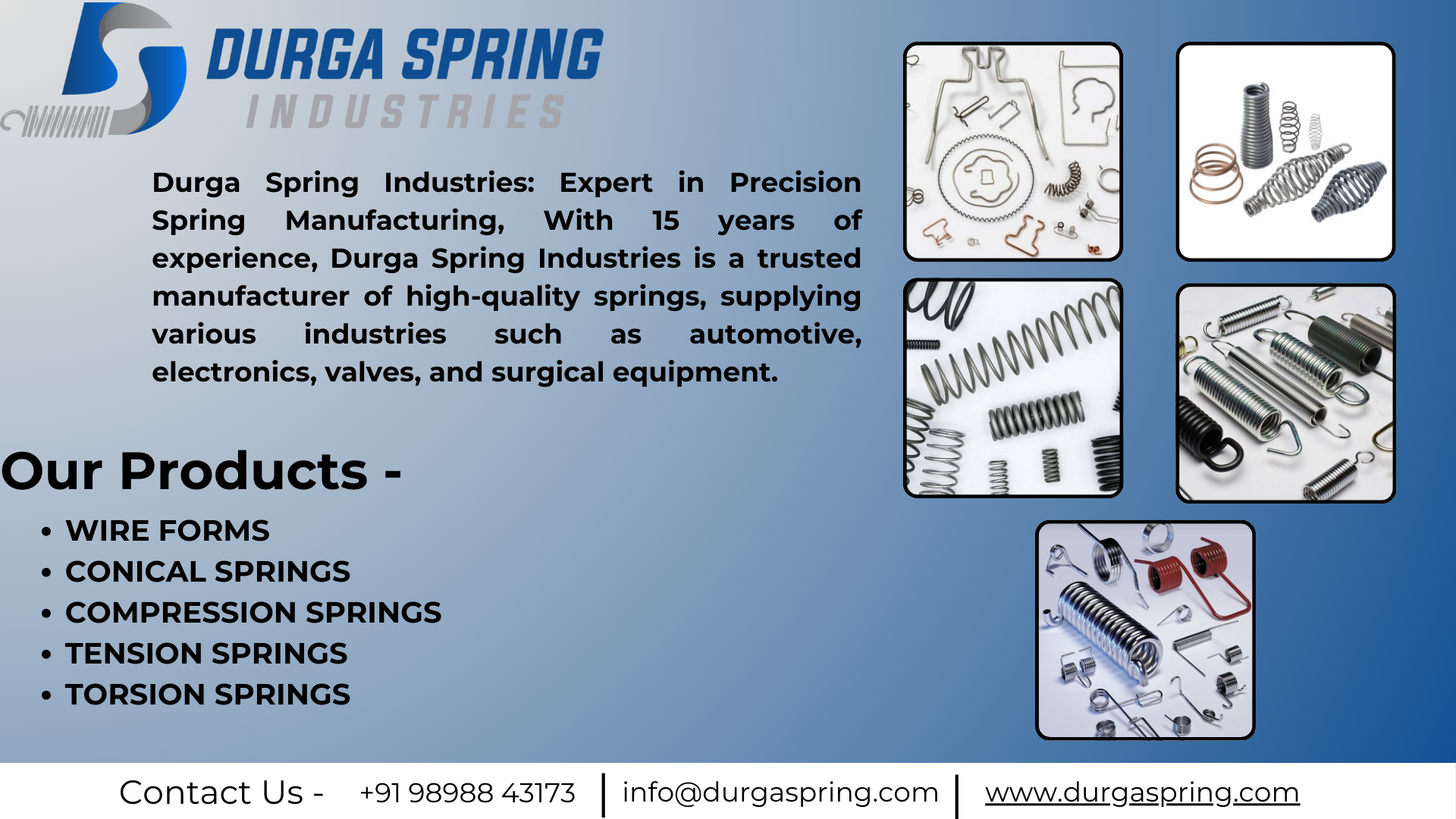

As one of the top spiral spring manufacturers in Ahmedabad, Durga Spring offers specialized manufacturing capabilities for precision flat spiral springs, also known as clock springs or power springs. These springs are crucial components in applications requiring consistent torque or rotational energy storage within a limited space. Located in Gujarat, we serve diverse industrial sectors, including automotive, electrical switchgear, and retraction systems, providing springs made from high-grade materials like stainless steel, high-carbon steel, and specialty alloys, ensuring superior fatigue life and reliable performance.

Our reputation as a leading spiral spring company in Ahmedabad is built on advanced manufacturing processes and strict quality control. We utilize:

Selecting the right partner is vital for spring performance. Durga Spring stands out among the **top spiral spring manufacturers in Ahmedabad** for delivering exceptional quality, engineering support, and reliable supply chain logistics across India. Whether you require a standard clock spring or a bespoke constant force spring, our team is equipped to handle your precise needs. Contact us today to discuss your spring requirements and benefit from the expertise of a trusted **leading spiral spring company** committed to excellence in manufacturing.

Durga Spring• We’re here to help

Filter Using Product Tags