Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

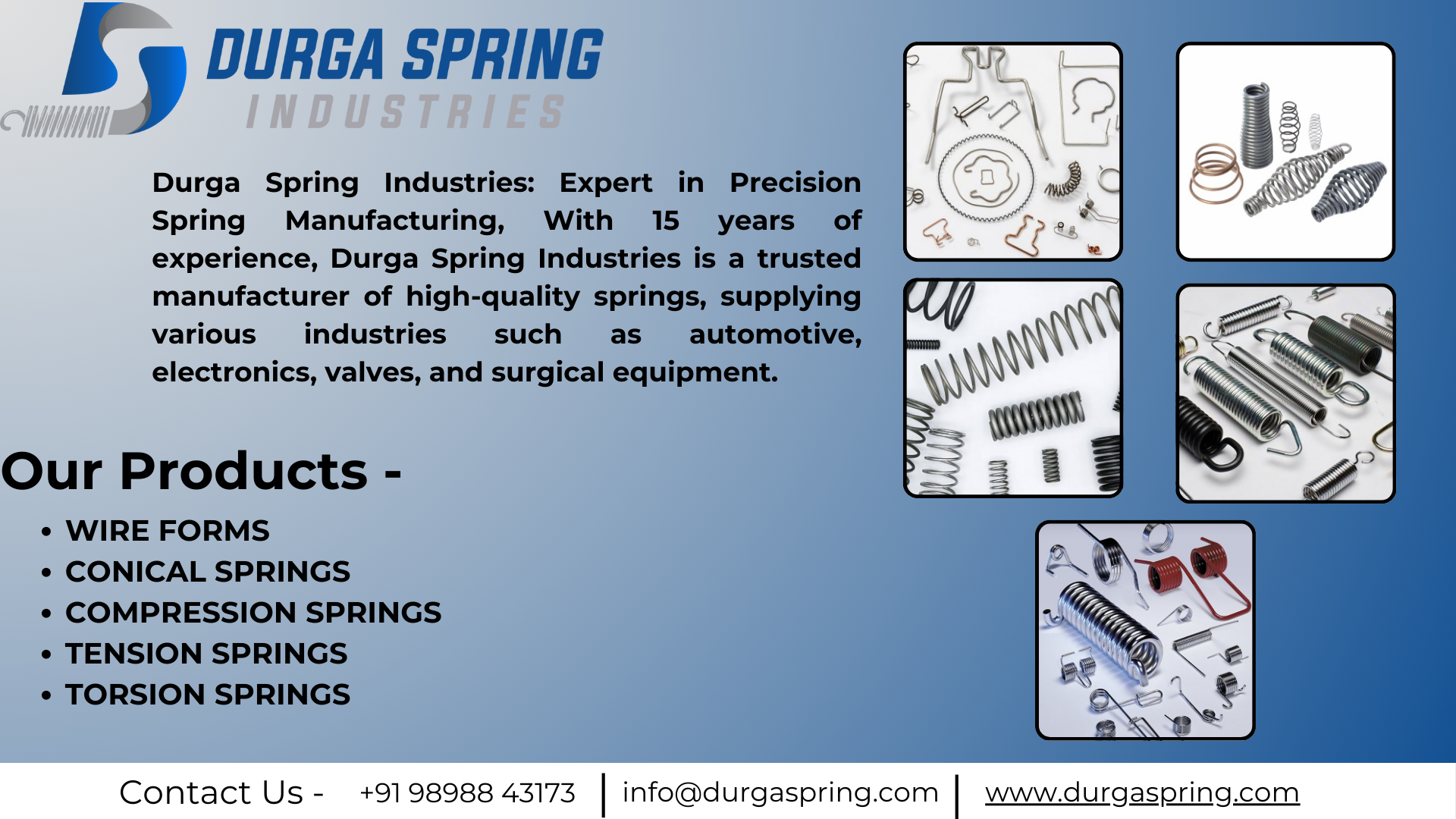

Tension Spring Manufacturer in Ahmedabad

Tension springs—also known as extension springs—are mechanical devices designed to absorb and store energy by resisting stretching force. As a trusted tension spring manufacturer in Ahmedabad, we produce high-precision springs that operate under tension and return to their original shape when the load is released. These springs are used across industries such as automotive, machinery, agriculture, electronics, and construction.

Tension springs are manufactured through a process involving:

Wire Selection: High-tensile steel, stainless steel, or galvanized wire is selected based on required strength and corrosion resistance.

Coiling: The wire is tightly wound into a helical coil using CNC spring coiling machines with precision pitch and tension.

Hook Forming: End loops, hooks, or eyelets are formed using automated machines or by hand depending on custom design.

Surface Coating: Springs are coated with zinc, paint, or powder to prevent rust and improve life.

Testing: Load and extension tests are performed to ensure accuracy and compliance with client specifications.

• Automotive brake systems and exhaust assemblies

• Door and window closures

• Washing machines and household appliances

• Weighing scales and agricultural equipment

• Industrial machinery and control systems

• Trampolines and exercise equipment

• Locking mechanisms and switches

• Elevators and garage doors

• Toys and mechanical gadgets

• Textile and packaging machines

• Precision-wound helix with consistent coil pitch

• Strong tensile strength and fatigue resistance

• Custom hooks or loop ends (German, English, side, extended)

• Available in different materials and finishes

• Resistance to corrosion and mechanical stress

• Available in light to heavy-duty load ranges

• Made to ISO, DIN, or client-specific standards

• Long service life with minimal maintenance

• Compact design with powerful restoring force

• Ready for small batch or bulk production

Tension springs play a critical role in holding components under tightness, ensuring secure positioning and responsive motion. In many dynamic and mechanical systems, they ensure reliable recoil action, energy storage, and consistent return force.

• Customizable in size, material, and tension strength

• Space-saving due to their compact form

• Low-cost solution with high mechanical efficiency

• Long-lasting even in high-cycle operations

• Available for low and high-load applications

• Fast replacement and easy installation

• Suitable for indoor and outdoor environments

• Resistant to deformation under stress

• Improves safety in machinery mechanisms

• Helps optimize performance in moving systems

Tension springs are essential in engineering, manufacturing, and everyday products. Their ability to provide force when stretched makes them integral in load control, movement regulation, and safety mechanisms. Manufacturers in Ahmedabad are supplying high-quality springs to meet India’s growing demand in sectors like automation, railways, and heavy industries.

• Over a decade of spring manufacturing expertise

• Custom tension springs made to drawing or sample

• CNC-controlled machines for high-precision production

• In-house design and R&D support

• Prompt delivery across India

• High-grade raw materials for performance and longevity

• Affordable pricing without compromising quality

• Strict quality checks and load testing

• Customer satisfaction and technical support focus

• Export-grade finish and packaging available

What materials are used for making tension springs?

Stainless steel, carbon steel, galvanized wire, and phosphor bronze are commonly used.

Can you make springs based on samples or drawings?

Yes, we specialize in custom springs as per client samples or technical drawings.

What is the maximum load your springs can handle?

We manufacture springs ranging from a few grams to several hundred kilograms of tension.

Are your springs rustproof?

Yes, we offer rust-resistant coatings like zinc plating and powder coating.

Do you provide small batch production?

Yes, from prototype to mass production, we cater to all order sizes.

Can these springs be used in wet environments?

Stainless steel springs are ideal for moisture-prone or outdoor use.

Do you supply to OEMs?

Absolutely. We supply to OEMs, exporters, and maintenance contractors.

How long does manufacturing take?

Lead time varies from 2 to 7 working days depending on quantity and design.

Do your springs meet industrial standards?

Yes, we follow IS, DIN, and other global mechanical standards.

Can I visit your factory in Ahmedabad?

Yes, factory visits are welcome with prior appointment.

Tension springs are vital for countless industrial and mechanical applications. As a reputed tension spring manufacturer in Ahmedabad, we ensure high-quality, performance-driven, and affordable spring solutions customized to your requirements. Whether you're in automotive, industrial machinery, or home appliances, our tension springs provide strength, durability, and performance that drives innovation forward.

Website:-https://durgaspring.com/

Filter Using Product Tags