Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

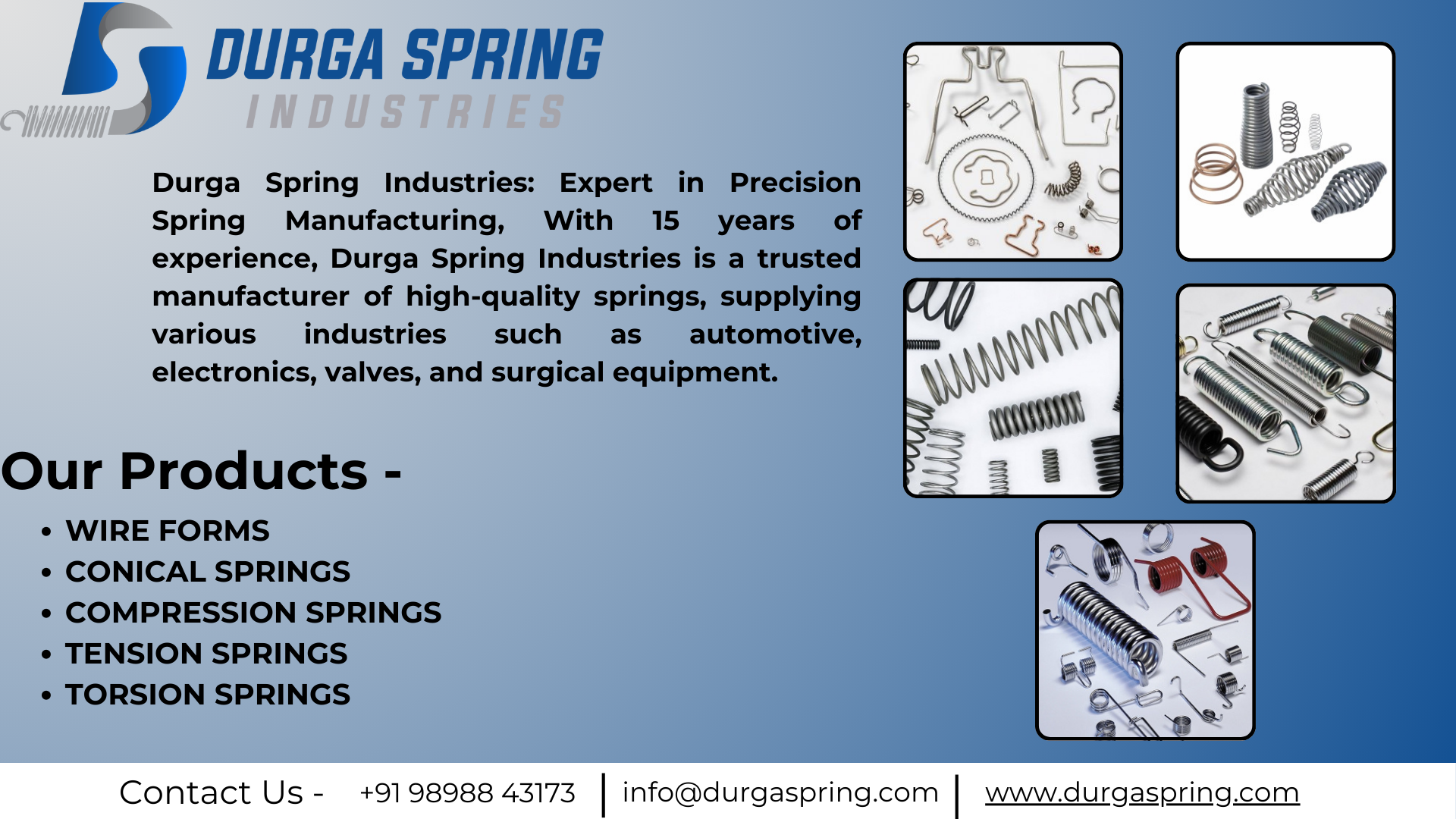

Durga Spring manufactures precision spiral springs across Gujarat, engineered for stable torque delivery, long fatigue life, and compact energy storage. Our flat spiral and power spring designs serve automotive mechanisms, retractors, timers, cable winders, and control devices. With CNC strip forming, controlled heat treatment, and surface finishing, we maintain consistent dimensions and repeatability for demanding OEM applications.

Quality at Durga Spring is built on process control and application-driven design:

Durga Spring• We’re here to help

Filter Using Product Tags