Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

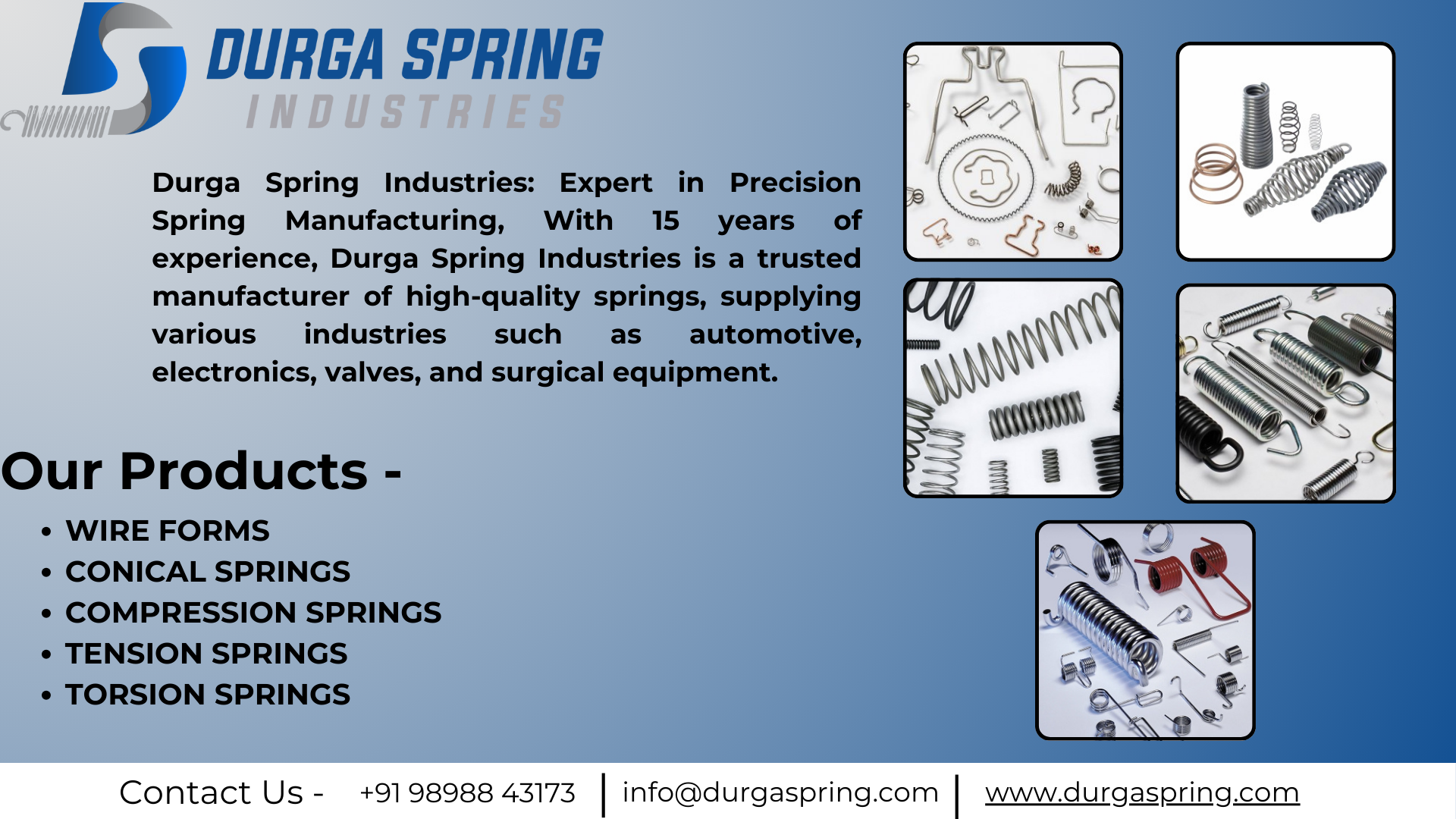

Durga Spring designs and manufactures spiral springs across India for mechanisms that demand repeatable torque and compact packaging. Our design team collaborates on torque windows, stroke limits, and housing geometry to deliver reliable performance from prototype to serial production.

We align product engineering with production readiness:

Durga Spring • We’re here to help

Filter Using Product Tags