Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

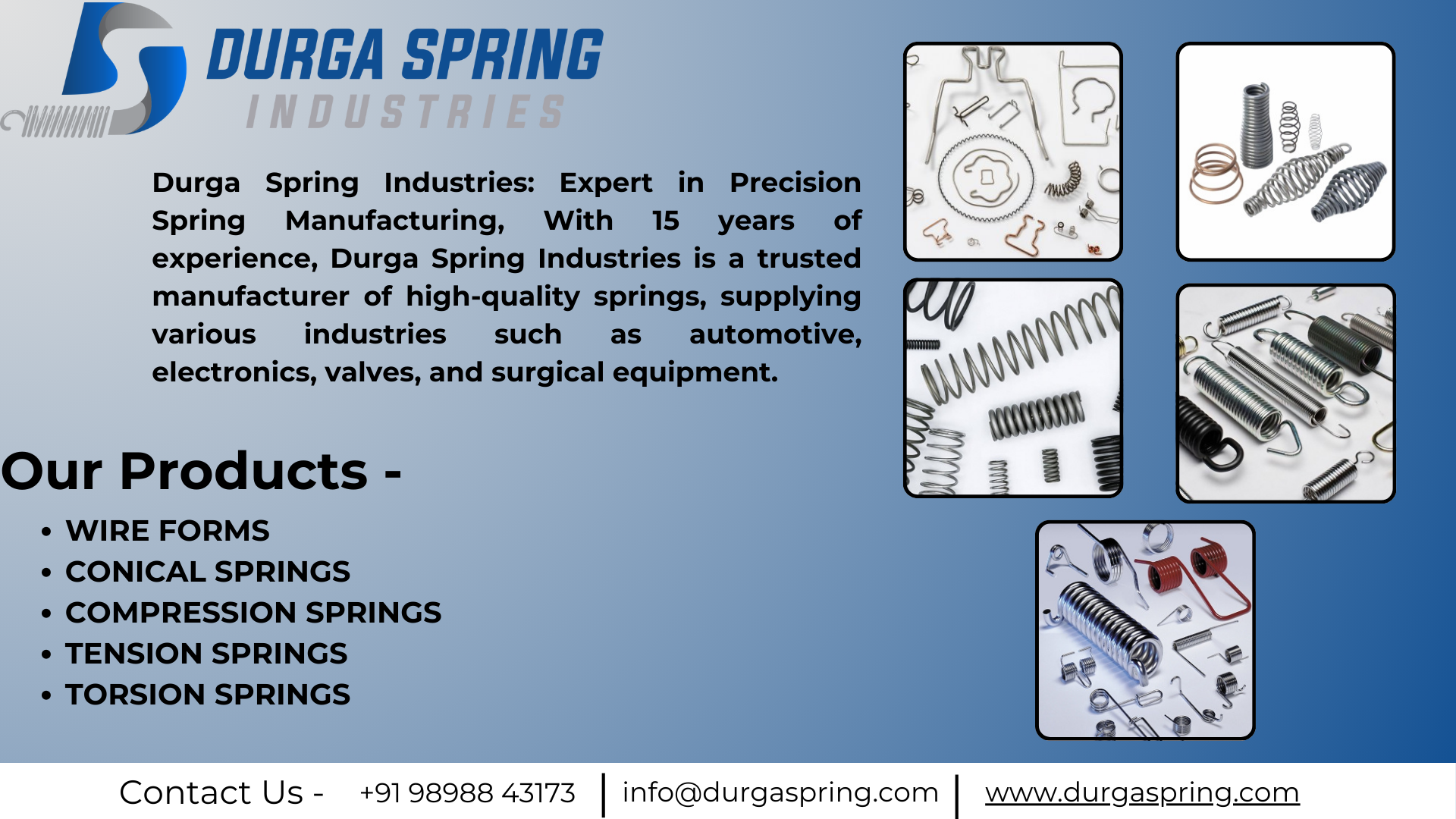

As a leading high-tensile die spring supplier in India, Durga Spring Industries provides engineered solutions for the most demanding applications. Our die springs are crafted from premium high-tensile steel alloys, such as Chrome-Vanadium steel, ensuring superior strength, durability, and a longer operational life. These springs are designed to handle high stress and fatigue cycles without premature failure, making them essential components in industries where reliability is paramount. Serving clients nationwide from our state-of-the-art facility in Ahmedabad, we guarantee a consistent supply of high-quality springs that meet both international standards and your specific performance needs.

The performance of a high-tensile die spring begins with its core material. Unlike standard springs, which use lower-grade steel, our springs are manufactured using high-tensile wire that provides an exceptional resistance to permanent deformation and fatigue. The process involves precision winding the wire on CNC machines, followed by a meticulous heat treatment process to optimize its mechanical properties. A specialized surface treatment, such as shot peening, is then applied to further enhance the spring's resilience by reducing surface stress. This rigorous multi-stage manufacturing process ensures that our high-tensile springs deliver consistent force and a significantly longer fatigue life, even in high-speed and high-stress operations.

Finding a reliable high-tensile die spring supplier in India requires a partner with a deep understanding of material science and manufacturing excellence. Durga Spring Industries has established itself as a top choice by focusing on these core principles. Our commitment to using the best raw materials and our rigorous quality control processes ensure that every spring we produce delivers on its promise of performance and longevity. With a robust distribution network, we serve clients efficiently and consistently across the country, providing superior products that outperform and outlast the competition. This nationwide reach, combined with our technical expertise, makes us a preferred supplier for businesses demanding the highest quality springs.

Durga Spring• We’re here to help

Filter Using Product Tags