Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Address

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

Plot No-10 Star Gold Industrial Park ,Opp Garda Ghar,Village Kuha, Ahmedabad Gujarat (India)-382433

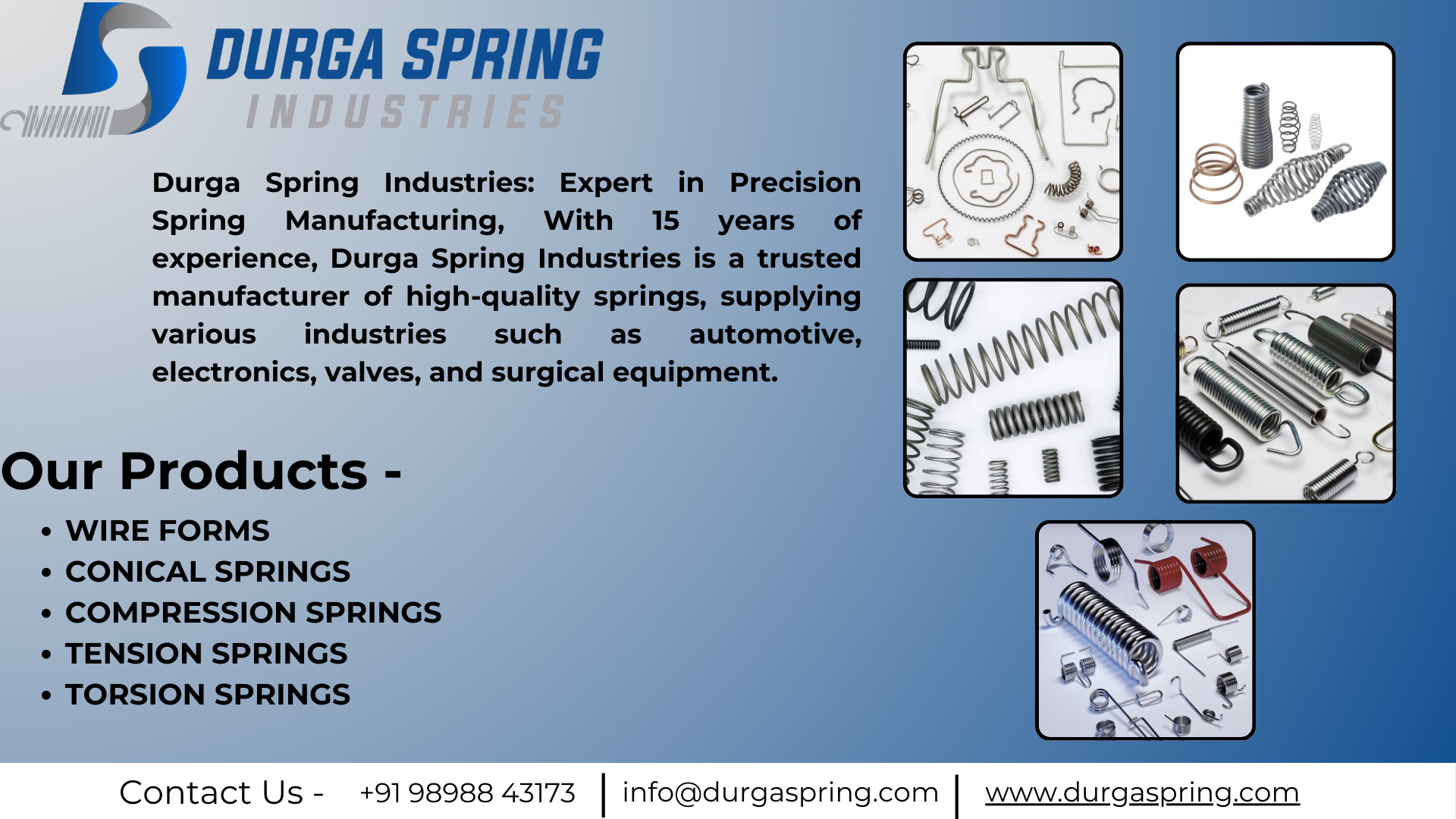

Durga Spring Industries, located in Ahmedabad, Gujarat, is a prominent die spring manufacturer in India, specializing in producing high-quality, durable, and reliable springs for die sets and press tools. With over 15 years of industry experience, we have become a trusted name for manufacturers across automotive, aerospace, industrial machinery, and consumer goods sectors. Our die springs are engineered to withstand extreme pressures and high-cycle applications, ensuring consistent performance and prolonged service life. We adhere to international color-coding standards (ISO, JIS) for easy identification of load ratings, guaranteeing precise application. With our state-of-the-art facility, stringent quality control, and commitment to innovation, Durga Spring Industries delivers robust and cost-effective die spring solutions that meet the demanding needs of modern industrial operations.

Die springs are a specific type of compression spring designed to handle high loads in small deflections. They work by storing and releasing a significant amount of force in a compact space, making them essential for applications like stamping, molding, and forming. At Durga Spring Industries, the process begins with selecting high-tensile chrome silicon or chrome vanadium steel wire. The wire is coiled to precise specifications, followed by a multi-stage process of heat treatment, shot peening for stress relief, and powder coating for color-coding and corrosion resistance. Each spring is rigorously tested for load capacity, deflection, and fatigue resistance to ensure it meets the highest standards for performance and reliability in demanding press and die applications.

In India, die spring manufacturers like Durga Spring Industries adhere to international standards for quality and load classification. The most common standard is **ISO 10243**, which uses a color-coding system to denote the load rating of each spring: yellow (light duty), blue (medium duty), red (heavy duty), green (extra heavy duty), and brown (ultra-heavy duty). This system is crucial for safety and efficiency, as it allows users to quickly select the correct spring for their application, preventing overload and premature failure. By following these standards, manufacturers ensure their die springs are interchangeable, reliable, and compatible with a wide range of die-set systems used globally, solidifying India's position in the precision spring market.

Durga Spring• We’re here to help

Filter Using Product Tags